Introduction to Types of Sensors

In this article, we will look at the different types of sensor but first, we will understand what sensor is? The sensor is equipment that detects any alterations and events in a physical input and gives the required output signals which can be recorded and referred for later use. The output signal is derived in electrical quantity. The word, sensors are also called as transducers and related to the measurement system. A good example of the sensor is a mercury thermometer that senses the heat or temperature in a system or human body. The temperature is measured from the calibrated glass body of thermometer based on contraction and expansion of liquid mercury. The origin of the word sensor is from the word ‘to perceive’

Types of Sensors

There are various classification of sensors that has different roles to perform from simple to complex operations. Some of the different physical input which too is measured is received in the below form:

- Acoustic: Inputs are measured by the wave, wavelength, velocity of the wave and spectrum

- Electric: Inputs which are to be measured are current, voltage, electric field, conductivity, and permittivity

- Agnetic: Inputs that to be calibrated are permeability, magnetic field, flux intensity

- Thermal: Terms to be measured are specific heat, thermal conductivity, and temperature

- Location, force, acceleration, pressure, volume, structure, rigidity, torque, momentum, stress and strain values, density and compliance are the mechanical form of inputs to be noted. Optical signals to be measured are wave velocity, absorption, refractive index, wave, and emissivity.

The above mentioned are some form of input that can also be converted to another form of output as required and noted and studied for future technologies.

The classification of sensor based on their different application is made as follows:

- Proximity

- Position

- Displacement sensors

The sensors which are used to measure the distance is a potentiometer. Then various sensors applied in this field are inductivity proximity sensors, optical encoders, eddy current proximity sensors, pneumatic sensors and hall effect sensors

- Light sensor: These are applied in the photodiode, light-dependent resistor, and phototransistor.

- Temperature sensors: They are employed in thermocouple, thermistors, and thermostats

- Motion and velocity sensors: They are deployed in Tachogenerator and incremental coder

- Tactile sensor and Piezoelectric sensors: They are applied to measure fluid pressure and diaphragm pressure gauge

- Liquid flow sensors: They are applied in orifice plate turbine meter and venturi tube

- Infrared sensor: They is used in a pair of infrared transmitter and receiver

- Force sensor: It is applied in strain gauge and load cells

- Touch-sensitive sensors: They are used in resistive and capacitive touch sensors.

- Ultraviolet sensors and photostability sensors: They are used to detect UV p germicidal UV detectors, phototubes, and ultraviolet light detectors.

The sensors are classified based on the requirement as Active and Passive sensors.

- Active sensors: Its work is based on power or signal from an external source. This signal which is fed is called an excitation signal and it produced the required output.

- Passive sensors: It directly give the output signal in corresponds to input messages.

The example of an active sensor is strain gauge which doesn’t generate its output signal but calculates the volume of applied pressure related to the resistance of the system. The resistance is calculated by passing a current through it. Here the current passed is called the excitation signal. The thermocouple is an example of a passive sensor.

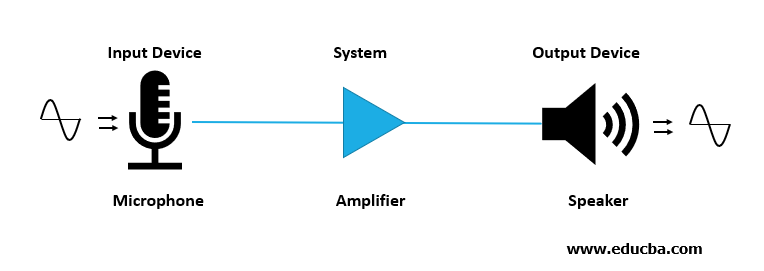

Working of a Sensor

The working and usage of sensors vary from device to device according to the demand. The sensor deployed in the public operating system was discussed here. The system consists of a microphone, loudspeaker, and amplifier. Here the sensor is used as an input function to the microphone which senses the sound waves and converts it to electric signals. Then its fed to the amplifier where the electric waves are given strength and amplified then fed to the loudspeaker.

The loudspeaker gets the output wave from the actuator where the electric waves from the amplifier are again converted to sound waves with more reach. The analog sensors give uninterrupted varying output waves with a set of values. The voltage is the output signal and is directly proportional to the measurand. The finite count that is measured like temperature, speed, strain, pressure are analog quantities and occurs continuously in nature.

The digital sensors generate discrete signals in digital.c The output of this sensor has ON and OFF states with the logic of 1 and 0. The push-button acts as a digital sensor. The switch has two possible conditions when pushed its ON, and when released it’s in OFF state. The light sensor is used to calculate the speed and generates a digital signal. The disc is connected to the motor’s shaft with a finite number of visible slots. The light sensor extracts the absence or presence of the light and gives logic 1 and 0 signals corresponding to the input.

Then the input is displayed on the speed and rotations of the disc. The accurate value is increased by slot increment in the disc and it allows more setup of slot simultaneously. The performance of digital and analog is compared where the accuracy of a digital sensor is high and represents the measurand with several bits used.

Advantages and Disadvantages of Sensor

Below are some of the advantages and disadvantages explained.

- Some of the limit switch sensors have a high current capability, require limited tech sensing, and available at low cost. The demerits of this limit switch sensor are it requires physical contact and have a very slow pickup time.

- The photoelectric sensors have a long durability, minimum response time, applied in long-range sensing devices, senses all forms of available energy and works effectively. But here the lens is prone to contamination and sensing range is impacted by color. The reflectivity of the target is reduced.

- The inductive sensors are very predictable, have a long lifetime, simple installation and are resistant to tough environments. In inductive sensors, the distance placed is the limitations to be rectified.

- The capacitive sensors identify non-metallic targets and also detect them through large containers. But they sensitive to environmental changes

- Ultrasonic sensors used to sense all the materials and are too sensitive to temperature changes. It has low resolution and repeatability.

Recommended Articles

This has been a guide to Types of Sensors. Here we discuss the working, types, advantages, and disadvantages of sensor respectively. You may also have a look at the following articles to learn more –