Updated April 26, 2023

Introduction to Concept of Six Sigma

As we finally made our place in the world market. So, it can be said without a doubt that to remain in that position quality of the product is of prime importance, and secondly comes the price. In this topic, we are going to learn about the Concept of Six Sigma. This is where the concept of Six Sigma needs to be introduced. Basically, it is a measure by which defects in production, manufacturing, and development of any product, as well as service, can be eliminated. Well, elimination of defects is not virtually possible but minimizing it to negligible.

Six Sigma principles are being introduced by companies today to lower the defect rate to a minimum. Various sectors as telecommunications, healthcare, finance, education, and the service industry are using this concept. It focuses on continuous improvement of the process; as a result, objectives and business goals are met in an efficient manner. Motorola and Bill Smith developed this concept when they were facing a lot of competition, and today it has become a Go-To concept adopted by many companies, namely, Infosys, Tata Consultancy Services, Wipro, Ford, Boeing, to name a few.

History of Six Sigma

- 1920 -1940 was the period when “Excellence through Inspection” was started. This was how the quality of products was maintained by a quality controlling inspection department in companies.

- 1940 -1960 showed us the “Statistical Process Control,” wherein statistical techniques were used to reduce variability in products, and this was how quality was controlled or rather maintained.

- 1960 – 1980 was the phase where companies starting adopting “Total Quality Management.” Organizations tuned towards total quality assurance.

- And 1987 and beyond is the Era of Six Sigma, and that is zero defects.

- So Six Sigma is a statistical-based approach and a method of continuous improvement that enables companies to eliminate defects in service, process, or most importantly, a product.

Customer Focus

Today’s customer has zero-tolerance. When there is so much competition, one cannot afford to lose a single customer as he will move on. As we all know that Brand Loyalty is a thing of the past now. A customer is where the best quality and best price are. When a customer is not satisfied with a product, it means the product has a defect, and according to six sigma, this defect has to be eliminated so that superior quality of goods and services can be manufactured and delivered.

Principles of Six Sigma

- Identifying the root cause of variations (defects).

- Actively eliminating variations and continuously improving the procedure.

- The focus should always be on the requirements of customers.

- Teams and leaders should be appointed and trained in Six Sigma’s methods so that they can serve properly.

- Flexibility and change should alhttps://www.educba.com/six-sigma-model/ways be a priority.

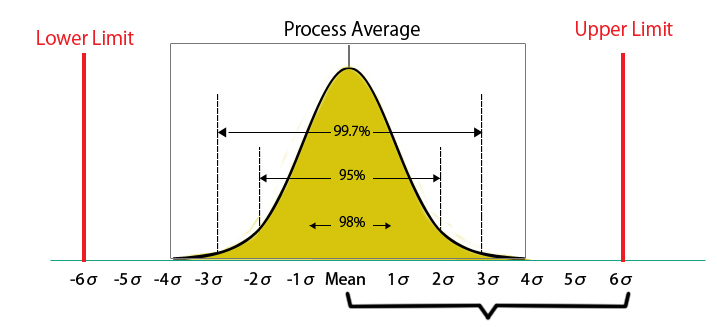

The graphic representation of sigma is a bell curve. It represents the standard deviation by which we measure the variation in the data that has been collected of a product. Each interval here is equal to one standard deviation or sigma. So, six sigma is plus/minus three sigma from the mean (average). Only a very minute number of defects will take place if this process is maintained.

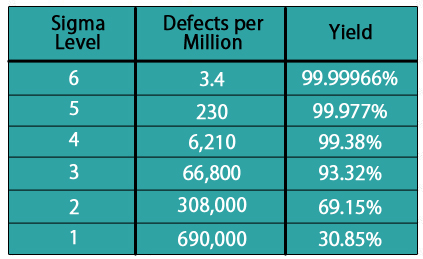

Statistically, when six sigma is achieved, the process must not produce 3.4 defects per million units of any product or opportunity.

Concept of Six Sigma Project

Whenever this six sigma project is implemented in any department of a company, well-constructed steps are taken, and targets are undertaken to improve production.

The points to be taken into consideration are:

- How to reduce the production cycle time?

- How to reduce the scrap generated from the production?

- How can one increase customer satisfaction?

- How to decrease the factory defects to negligible?

- How to reduce the cost of reworking?

All of the above will definitely bring an improvement in not only the manufacturing industry but will also elevate the office or business process and also the service process.

Implementation of Six Sigma

First and foremost, measuring the current variation is of utmost importance. Variation can never be eliminated to a zero. Variation is inherent. But it can definitely be reduced. To reduce it needs to be measured, and to measure, one needs to focus, and wherever there is the focus, there is an improvement. Thus a process has to be selected. To this, the six sigma project has to be applied. If there is an improvement, it will definitely show in the form of better quality, increased productivity and reduced wastage, lower cost of production, and a higher level of customer satisfaction.

Five Phases of Six Sigma

Below are the 5 phases of six sigma:

1. Define

It is extremely important to define the problem that needs to be fixed. Leaders have to identify and then address the issue. Defining the process which is unproductive is the beginning of this procedure.

2. Measure

A team has to collect data on the current process that is being performed. Only when data is collected it and one has numbers in hand there can be a scope for improvement.

3. Analyze

After the collection of data, the team then reviews the data. Analyzing this data and the process together leads to the reason for wastes, defects, etc.

4. Improve

It is time for the heads of the company to now come together to find a solution. Ideas can be collected within the company as well as outside. The correct solution will definitely result in improvements.

5. Control

Though improvement has been achieved, passing this structure to the employees who have been working in the earlier process is of great importance. This process is called the Control phase, where one needs to maintain the improvement achieved.

Conclusion – Concept of Six Sigma

Another Six Sigma method that is widely employed is the DMADV method. This involves the Design of the procedure, ensuring customer satisfaction, Measure the parameters required for quality maintenance, Analyze so that an alternative is always present to maintain the superior quality, Design the details, and finally, Verify all the processes before implementing them. The main focus here is how to make better or improve the business methods already adopted by the organization.

Recommended Articles

This has been a guide to Concept of Six Sigma. Here we discussed the basic concept, project implementation, and the five phases of Six Sigma. You can also go through our other suggested articles to learn more –