- Course Overview

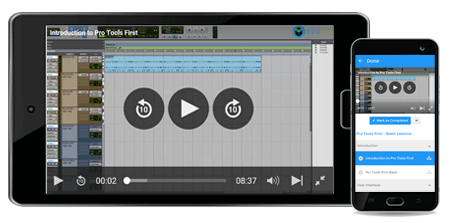

- View Offline

Course Overview

About Online Six Sigma Primer Training:

- Six sigma is a set of techniques and tools for improving the process. It was created by Motorola. At General Electric Jack Welch made his business strategy central and he wanted everyone to know about it. Today in many industrial sectors this sigma green belt is used greatly.

- Six sigma searches out to improve the quality of process outputs by identifying and removing the causes of defects (errors) and minimizing instability in manufacturing and business processes.

- It uses a set of quality management methods, which includes statistical methods, and creates a special infrastructure of people within the organization (“Champions”, “Black Belts”, “Green Belts”, “Yellow Belts”, etc.) who are great scholars in these methods. Each Six sigma project carried out in an organization follows a specified sequence of steps and has estimated value targets, for example: reduce process cycle time, reduce pollution, reduce costs, increase customer satisfaction, and increase profits.

- These are some core principles of Total Quality Management (TQM) as described by Peter Drucker and Tom Peters.

- The term Six sigma originated from term associated with manufacturing, specifically terms associated with statistical modeling of manufacturing processes.

- The maturity of a manufacturing process can be described by a sigma rate which indicates its product or the percentage of defect-free products it creates.

- A Six sigma process is one out of many in which 99.9% of the result i.e. products made are expected to be free of defects according to the rates or percentage in every year (3.4 defective parts/million), although, as discussed below, this defect level equals to only a 4.5 sigma level. Motorola sets a goal of “six sigma” for all of its manufacturing operations, and this goal became a catchword for the management and engineering practices used to achieve this Six sigma concept.

- The Six sigma Green Belt operates in support of or under the supervision of a Six sigma Black Belt which analyzes and solves quality problems and is involved in improving quality of projects. A Green Belt is someone who has at least three years of work experience who wants to demonstrate his or her knowledge of Six sigma tools and processes.

- Green Belts are workers of an organization who have been trained on the Six sigma improvement of projects methodology and will head as a process improvement team as part of their full-time job. While Green Belts not necessarily should know as much Black Belts or Master Black Belts knows, there are many things a Green Belt should know.

- To gain Six sigma quality, a process must produce no more than 3.4 defects per million opportunities. An “opportunity” is defined as a chance for non-compliant, or not meeting the required specifications. This means we need to be nearly perfect in executing our key processes. Six sigma is a range of view we aim towards and a philosophy that is part of our business culture.

Mainly, six sigma revolves around a few main concepts that are mentioned below:

- Critical to Quality: Attributes is the most important factor to the customer

- Defect: Failing to deliver what customer wanted

- Process Capability: What your process can deliver

- Variation: What the customer looks and feels

- Stable Operations: Ensuring consistent, predictable processes to improve what the customer sees and feels

- Design for Six Sigma: Designing to meet customer needs.

Six sigma has mainly 3 various levels:

1. Metric level

2. Methodology level

3. Management system level

Essentially, Six sigma is all three at the same time.

Six sigma is a business improvement methodology that focuses an organization on:

Understanding and managing what customer requires

Aligning key business processes to achieve those requirements.

Utilizing rigorous data analysis to minimize changes in those processes.

Driving fast and stable improvement to business processes.

The most important thing of the methodology is the DMAIC model for process improvement. DMAIC is commonly used by six sigma project teams and its long form is given below:

- Define opportunity.

- Measure performance

- Analyze opportunity.

- Improve performance

- Control performance

What is the need of Six sigma green belt training?

- Six sigma Green Belt training will quickly put you into a very active role in the Six sigma team. Green Belts are those certified people in the Six sigma teams that are not compulsory for assuming leadership positions.

- Green Belts are the ‘worker bees’ of Six Sigma, and do not have the proper training for the leadership roles even if they want to be a leader.

- Six sigma Green Belt training will cover all the concepts that are essential to the Six sigma methodologies, but leadership skill will not be as necessary at this level.

- Those who go through this training will begin their training with a brief introduction of Six sigma as a whole and the reasons that companies opt to use the Six sigma methods. Green Belt training will then lead into breaking down the DMAIC paradigm, which stands for Define, Measure, Analyze, Improve and Control. The breakdown of the DMAIC processes allows the Green Belt students to become familiar with the processes and Six sigma methodologies that are responsible for the improving the business processes.

- The in detail information that should be known about the DMAIC processes should be what Six sigma Green Belt training courses are mainly centered around. Of course, team work will be another important part of Green Belt training. Green Belts will be team players; therefore, there will be working on communication skills and the Green Belt students who will be given training to know their specific roles in the Six sigma team.

- The Green Belts are just as important, if not more important than the other levels of Six sigma belts and other designated specialty levels and this green belt students must realize the importance of their role in the team.

- One of the supreme benefits of a Six sigma Green Belt certification is to improve efficiency in the workplace. This can be achieved by reducing waste in the form of production cycle times and delays. A Six sigma Green Belt is basically involved in problem-solving groups and is able to prevent defects and correct the errors in the production process, which results in maximizing the result.

Teamwork: second important benefit is teamwork. As all the team will work together and will able to solve problems quickly. Work will be done faster as well.

Course goals and objectives:

- Learn in details what ERP system is and how it works in industry

- Learn SAP, SAP system and its architecture which is taught efficiently in this tutorial.

- Learn SAP IDES and its navigation with basic to advanced level.

Target Audience:

- Six sigma Green Belt training programs are great option for business owners who have employees that want to be part of a team and they are a great option for those who want to further their career options.

- Those who are not interested in leadership roles will be most comfortable at the level of Six sigma Green Belt.

- Six sigma Professionals who wants to become expert in it can go with this course.

- Six sigma aspirants who want to take their company very high with benefits should learn Six sigma green belt topic.

- Project Managers

- Students looking for a career in Six sigma should definitely take this course because basic is being taught in this tutorial.

Pre-Requisites:

- A computer with internet is needed as online learning will be there. Don’t skip any video as all are interconnected and if gets missed then further part will be difficult to understand.

- Eagerness to learn Six sigma Green Belt.

- No important requirements needed as such for undergoing this course; however basic understanding of statistics would help learners to grab the knowledge of subject thoroughly.

Six sigma Green Belt Training Advantages:

- Those who become Green Belt certified may find that they want to move up the Six sigma ladder to become a Six sigma Black Belt or other Six sigma specialty.

- How to solve business and quality problems

- To improve decision making ability

- To improve overall performance of the enterprise

- Will learn how to add business and analytical skills.