Introduction to Digital Signage in Manufacturing

Warehouses have evolved dramatically from spaces filled solely with human workers to environments where machines and automation play an integral role. The sight of robotic arms, conveyor belts, AI-powered systems, and digital signage in manufacturing has sparked concerns about human redundancy. However, the truth is far from simple.

Automation is not here to replace human workers but to collaborate with them. One crucial element enabling this collaboration is digital signage for manufacturing. Acting as the communication bridge between humans and machines, digital signage helps streamline operations, enhance safety, and optimize productivity.

This article explores how digital signage facilitates the human-machine partnership, ensuring a more intelligent and efficient warehouse ecosystem.

The Role of Digital Signage in Manufacturing

Digital signage in manufacturing is more than just screens displaying information. It acts as the warehouse’s central nervous system, offering real-time data, facilitating communication, and improving decision-making. By integrating digital signage with automation, warehouses can create an efficient and adaptive work environment where human workers play a vital role.

Rather than fearing automation, businesses should focus on harnessing its potential while leveraging human adaptability. Digital signage in manufacturing ensures that workers remain informed, engaged, and empowered in an evolving workspace.

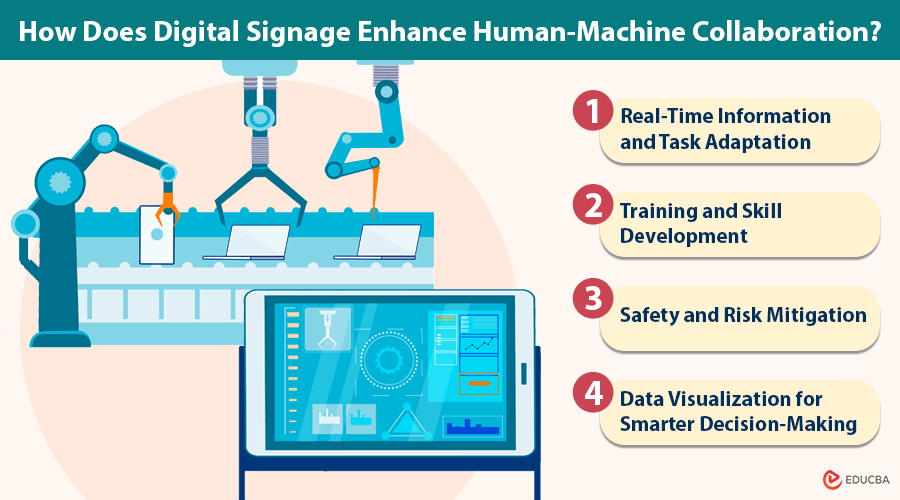

How does Digital Signage Enhance Human-Machine Collaboration?

Automation handles repetitive and physically demanding tasks, but human workers bring critical thinking, problem-solving, and adaptability to the warehouse. Digital signage in manufacturing helps merge these strengths by transforming data into meaningful insights that guide workers effectively.

1. Real-Time Information and Task Adaptation

Warehouses operate in a dynamic environment, requiring continuous adjustments. Digital signage provides:

- Adaptive task allocation: If a robotic system encounters an issue, digital displays instantly notify workers, guiding them to troubleshoot the problem.

- Predictive problem-solving: Digital signage shows early warnings about potential malfunctions, allowing proactive maintenance and preventing costly breakdowns.

- Contextual guidance: Workers receive real-time feedback on proper lifting techniques and ergonomic practices, reducing workplace injuries.

Digital signage in manufacturing significantly boosts operational efficiency by ensuring that human workers are always aware of their tasks and potential disruptions.

2. Training and Skill Development

The future of warehousing demands workers who can analyze, adapt, and manage complex systems. Digital signage transforms warehouses into ongoing learning spaces by offering:

- Scenario-based training: Workers can engage in simulated troubleshooting exercises to develop problem-solving skills in a safe, controlled environment.

- Personalized performance feedback: Employees receive insights into their strengths and improvement areas, fostering continuous skill development.

- Knowledge-sharing networks: Digital signage connects workers to training materials, expert forums, and collaborative platforms, promoting a learning culture.

Instead of relying on outdated training methods, digital signage in manufacturing ensures that warehouse staff constantly upgrade their skills alongside automation advancements.

3. Safety and Risk Mitigation

Automation introduces new workplace hazards. Digital signage acts as a vigilant safety tool by providing:

- Dynamic hazard mapping: Safety zones are updated in real-time, reflecting changes in robot movements and material handling areas.

- Predictive risk alerts: Environmental sensors detect potential risks, such as overheating machinery or obstructions, warning workers before accidents occur.

- Personalized safety notifications: Workers receive safety reminders tailored to their tasks, ensuring a proactive approach to injury prevention.

With digital signage in manufacturing, warehouses can significantly enhance safety by ensuring seamless collaboration between human workers and automation.

4. Data Visualization for Smarter Decision-Making

Automation generates massive amounts of data, but raw numbers mean little without interpretation. Digital signage converts data into actionable intelligence, enabling workers to:

- Monitor inventory in real-time: Workers can view inventory trends, preventing shortages or overstocking.

- Analyze performance contextually: Instead of focusing only on individual metrics, digital signage presents a broader view of warehouse efficiency.

- Facilitate collaborative problem-solving: Teams can use data to identify inefficiencies and develop effective solutions.

Rather than drowning in data, digital signage in manufacturing ensures workers access the right information at the right time to make informed decisions.

The Future: Humans and Automation Working Together

Do not view warehouses as battlegrounds between humans and robots. Instead, they are ecosystems where both can thrive together. Digital signage is pivotal in ensuring that automation supports, rather than replaces, the workforce. Here is how:

1. Task Synchronization

Digital signage provides a shared workspace where workers and machines remain in sync. This ensures that:

- Automated systems align with human workers in real-time.

- Tasks are distributed based on real-time demand.

- Warehouse operations run smoothly, minimizing delays.

2. Human-Robot Interaction Design

Humans and robots must work smoothly together for efficiency. Digital signage enables:

- Easy-to-use interfaces that allow workers to control and communicate with automation systems.

- Intuitive visual instructions that simplify complex machine processes.

- A workspace where humans and robots work together, using each other’s strengths.

3. Workforce Optimization

Digital signage in manufacturing uses real-time data to assign tasks based on employees’ skills and availability. This approach enhances:

- Skill-based task assignment: Workers get tasks that fit their skills, boosting efficiency and job satisfaction.

- Dynamic team formation: Digital signage facilitates quick team restructuring when urgent issues arise.

- Continuous feedback loops: Managers can monitor performance and provide instant feedback, fostering a culture of growth and adaptation.

Final Thoughts

Automation is reshaping the warehouse industry, but it does not mean the end of human involvement. Instead, automation and human workers are entering a new phase of collaboration, where digital signage acts as the unifying force.

By providing real-time data, facilitating communication, and enhancing safety, digital signage in manufacturing ensures that human workers remain essential in the automated warehouses of the future. It transforms the warehouse into an efficient, safe, and knowledge-driven space where humans and machines work together seamlessly.

The future is not about choosing between humans and robots but about empowering both to reach their full potential through smart collaboration. With digital signage leading the way, warehouses can unlock new productivity levels, innovation, and human-machine synergy.

Recommended Articles

We hope you found this update insightful. Check out these recommended articles for more insights on manufacturing automation, workplace safety, and digital transformation trends.