What is Inventory Control?

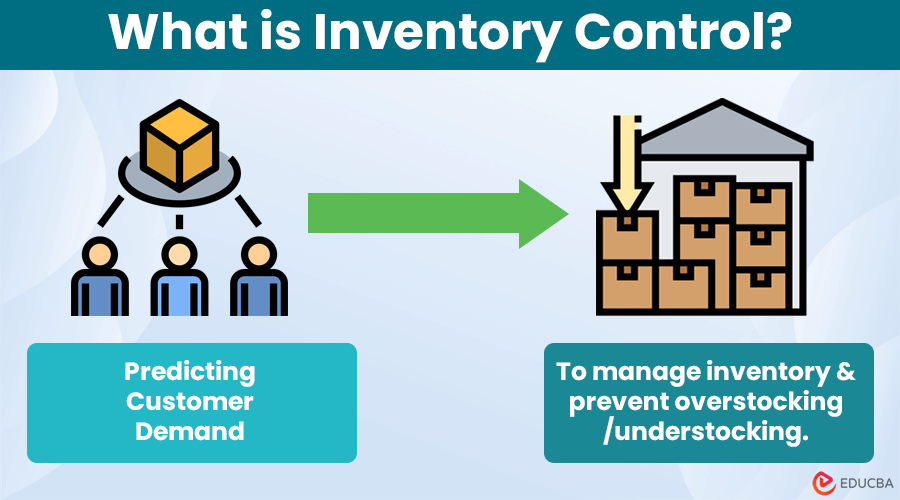

Inventory control is when companies manage and adjust their inventory to make sure they have enough items to meet customer demand without overstocking.

Inventory control is essential for companies of all sizes and industries, from small retailers to large manufacturers. Companies can analyze data on sales trends, customer behavior, and other factors to identify product demand and optimize their inventory management processes accordingly.

Table of Contents

Inventory Control Process – How Does It Work?

Effective inventory control involves the following two steps:

#1: Demand Forecast: This involves analyzing historical data and current trends to understand demand. By accurately forecasting demand, businesses can determine the optimal level of inventory needed without overstocking or understocking.

#2: Monitor inventory levels: This involves regularly tracking inventory levels and adjusting orders accordingly. For example, if sales are higher than expected, a business may need to order more inventory to avoid stockouts.

Inventory Control Example

A restaurant uses the following steps to employ effective inventory control.

Step 1: Analysis and Prediction

They analyze their previous month’s sales and conclude that they sold 120 meals per day during weekdays and 350 meals per day on weekends.

Step 2: Calculating Demand for Month 1

The restaurant uses the data report to determine their monthly average customer demand.

| Weekdays: | 120 meals/day x 20 days | 2,400 meals |

| Weekends: | 350 meals/day x 8 days | 2,800 meals |

| Total meals for Month 1 | 5,200 | |

According to the calculated demand, the restaurant procures enough inventory to fulfill orders for 5,200 meals.

Step 3: Adjusting Inventory Based on Increased Demand

The restaurant predicts a 10% rise in demand next month because of holidays like Thanksgiving or Christmas. To factor this into their inventory management, they make the following calculations.

| Weekdays: | 132 meals/day x 20 days | 2,640 meals |

| Weekends: | 385 meals/day x 8 days | 3,080 meals |

| Total meals for Month 2 | 5,720 | |

Thus, after anticipating a 10% increase in overall demand, the restaurant adjusts its inventory accordingly.

Conclusion:

Therefore, by predicting busy periods, the restaurant adjusts its inventory purchase. During peak times, for instance, on weekends, they order more inventory than usual. Furthermore, they buy less inventory than usual during slower days, like mid-week. This way, they can use inventory control to optimize costs and maintain quality service for customers.

Inventory Control Techniques/Methods

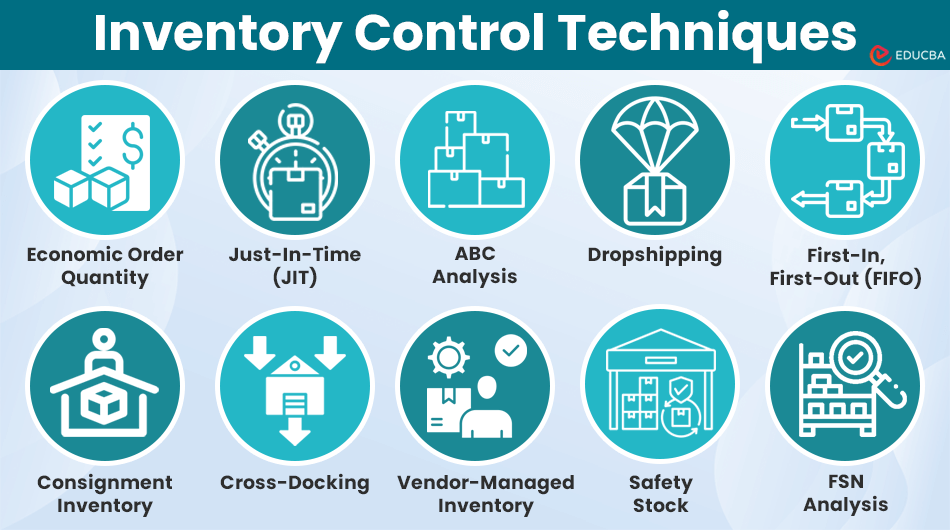

Here are some of the common methods of inventory control that businesses can use:

- Economic Order Quantity (EOQ): It calculates the optimal order quantity based on demand, lead time, and ordering costs. It assists businesses in optimizing their inventory levels and reducing waste.

- Just-In-Time (JIT): This method involves ordering or producing goods only as they are needed. It helps businesses reduce inventory carrying costs and increase efficiency.

- ABC analysis: This method classifies inventory items as “A,” “B,” or “C,” depending on how valuable they are to the business. “A” items are the most critical, and “C” items are the least important. This way, businesses can allocate resources better, focusing more on managing high-value items and less on lower-value ones.

- Dropshipping: In this model, businesses work with vendors who send goods straight to clients when ordered. In this model, businesses work with vendors who send goods straight to clients when ordered, which makes dropshipping business attractive for most people.

- First-In, First-Out (FIFO): FIFO is a method where, to minimize the risk of inventory spoiling or obsolescence, firms give priority to selling the oldest stock items first. By prioritizing the sale of older inventory, businesses can reduce the likelihood of holding onto products for too long.

- Consignment Inventory: In this method, suppliers hold inventory on behalf of the business, helping businesses reduce inventory carrying costs and increase efficiency.

- Cross-Docking: This method helps companies accelerate the flow of goods. Companies directly load incoming shipments from suppliers onto outbound trucks for delivery rather than keeping them in a warehouse.

- Vendor-Managed Inventory (VMI): In VMI, the supplier keeps track of their products at the customer’s place and refills them when necessary.

- Safety Stock: In this scenario, businesses keep extra inventory than required, known as safety stock. It reduces the risk of stockouts (unavailability of products) because of any unexpected changes in demand or other issues.

- FSN Analysis: This method sorts items into three categories: Fast-moving, Slow-moving, and Non-moving. Fast-moving items sell quickly, while slow-moving ones sell less often. Non-moving items haven’t sold within a set time. FSN analysis helps businesses focus resources and make decisions on purchasing, stocking, and pricing.

Types of Inventory Control System

An inventory control system uses technology to automate inventory tracking and forecasting. These systems can help businesses optimize inventory levels, reduce stockouts and excess inventory, and improve overall supply chain efficiency. For businesses looking for a comprehensive solution, the best PSA software often includes robust inventory control features, helping companies streamline inventory tracking, automate replenishment, and ensure accurate stock levels in real-time. There are various types of inventory control systems. Here are the most common types:

- Periodic System: Under this system, businesses manually count their inventory items at set periods, like weekly, monthly, or quarterly. Periodic systems update records only after physical counts. Therefore, this method can sometimes lead to discrepancies between recorded and actual inventory quantities.

- Perpetual System: It is an automated method that uses technologies or software to monitor inventory in real-time, giving up-to-date information on inventory levels. This method involves continuously tracking inventory levels using barcode scanners, RFID, and inventory management software.

- Barcode: Each product has a unique barcode that companies scan at several points along the supply chain, like when they sell or receive the item. This way, the technology offers precise and timely information on inventory levels.

- RFID: RFID (radio-frequency identification) technology is similar to barcode tracking. Each item has an RFID tag attached, and the business uses radio waves to scan the tags to keep track of inventory items as they move.

Importance

Inventory control is important for effective supply chain management. The following are some of the key reasons why it is essential for businesses:

- Avoid Stockouts: One of the most critical reasons for inventory control is to avoid stockouts. Unavailability of inventory can lead to reduced sales, decreased revenue, and lower customer satisfaction.

- Reduce Waste: Overstocking can lead to waste and obsolescence. When businesses have too much inventory, they may be unable to sell it all, leading to lost resources. Thus, with inventory control, businesses only order the necessary inventory, reducing waste and saving valuable resources.

- Increase Efficiency: It can help businesses increase efficiency by streamlining their operations. By accurately forecasting demand and monitoring inventory levels, businesses can optimize their supply chain and manage inventory using limited time and resources.

- Improve Cash Flow: Managing inventory levels can help businesses improve their cash flow. By avoiding overstocking, businesses can avoid tying up valuable resources in inventory that may not sell. It frees up cash to invest in other areas of the business.

- Improve Customer Satisfaction: It also helps businesses improve customer satisfaction, which in turn improves customer loyalty. Businesses can avoid disappointing customers with out-of-stock items by ensuring that products are always in stock.

- Optimize Profitability: It is crucial for optimizing profitability. By accurately forecasting demand and monitoring inventory levels, businesses can optimize their inventory levels and reduce waste. It can lead to increased profitability and improved bottom-line results.

Frequently Asked Questions (FAQs)

Q1. What are the objectives of inventory control?

Answer: Inventory control helps businesses fulfill the following objectives:

- Ensure the firm maintains correct inventory levels to meet customer demand, avoiding shortages or excess stock.

- Cut down costs of storing inventory, like warehouse rent, insurance, and obsolescence.

- Efficiently manage inventory to minimize tied-up capital.

- Improve productivity, reduce waste, and enhance operational efficiency by streamlining inventory management processes.

Q2. Mention some advantages of inventory control.

Answer: Some advantages of inventory control are cost reduction, improved customer service, better cash flow management, reduced risk of obsolescence, and enhanced decision-making.

Q3. What are some challenges of inventory control?

Answer: One of the most significant challenges of inventory control is accurately forecasting demand. If a business underestimates demand, it may run out of stock and lose sales opportunities. On the other hand, overestimating demand can mean companies store more inventory than required, which can increase expenses.

Inefficient tracking and management of inventory is another common challenge for businesses. Manual inventory tracking processes can be time-consuming and error-prone, leading to inaccurate data and poor decision-making.

Recommended Articles

We hope you found this article on inventory control helpful. For similar articles, visit the following links.