Difference Between Lean Six Sigma vs Six Sigma

The following article provides an outline for Lean Six Sigma vs Six Sigma. Every company works to earn a profit, which will only happen when there is holistic use of resources properly so that there should be a minimum waste of resources and productivity is high. So every type of company, whether related to manufacturing, corporate, and others, also focus mainly on the minimum waste strategy. So to overcome these problems, management thinkers come up with some universal principles which are applicable to all types of companies and industries, which they name as Six Sigma. These principles or rules determine some parameters to reduce the waste so that there should be high productivity but with less input of resources.

Both these are found by different companies and have an impeccable reputation in their individual spheres. Also, both are different, where one works for the efficiency of other work for the quality in the industry. As far as the lean sigma and six sigma both are concerned, both these principles act for a common cause but with different angles of work. Ultimately the issue is not for the selection of these two but how to apply these two appropriately so that these may enhance the business.

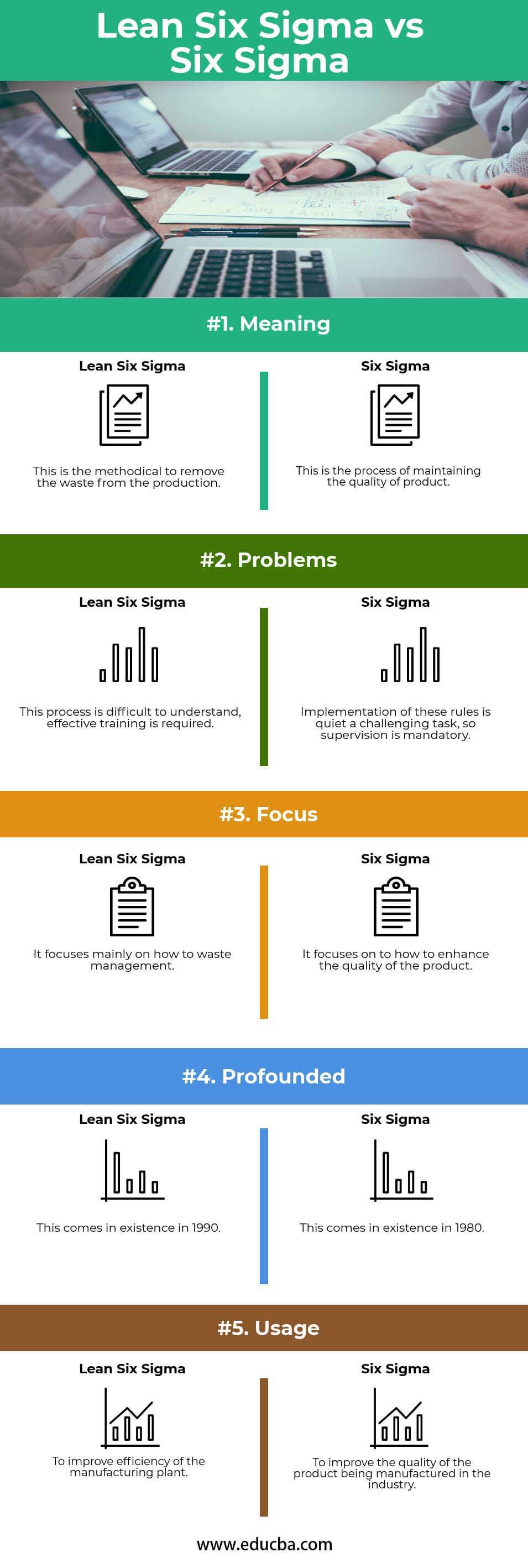

Head to Head Comparison Between Lean Six Sigma vs Six Sigma (Infographics)

Below are the top 5 difference between Lean Six Sigma vs Six Sigma:

Key Differences Between Lean Six Sigma vs Six Sigma

Both Lean Six Sigma vs Six Sigma are popular choices in the market.

Let us discuss some of the major difference Between Lean Six Sigma vs Six Sigma:

- The lean six sigma was developed by the company Toyota, Whereas Motorola introduced the Principles of Six Sigma.

- Lean six sigma focuses on the way to eradicate waste from the process in the organization. On the other hand, Six sigma emphasis the quality of the product by illustrating some universal principles.

- If we talk about the tool used in both the processes, so we see that Lean depends on the visuals, and on the other side, six sigma used mathematical and statistical methods for the prorogation.

- The use of Lean six sigma in the production results in uniformity in the output, and if we talk about the six sigma as we discussed above, it gave some universal methods to do work so it affects the speed of the process, which leads to less production(Because to get quality compromise should be done with quantity).

- There is less need for proper supervision when lean six sigma is implemented; on another side, there is a proper need for supervision to check the parameters in six sigma operations because quality will achieve only by minute work and holistic work.

- The principles on which the lean six sigma works are – the flow of activities, perfection, identification of value, etc. on another side, six sigma work on its basic rules, which are defined, measure, analyze, improve, control, etc.

- There are basically two concepts of lean six sigma, which are just in time (JIT) and Jidoka, and if we consider six sigma, it has DMAIC and DMADV.

- The lean six sigma is used by many MNC’s and other firms like Abbot, Textron, Xerox, etc., and on another side, six sigma has very well prevailed in the Indian origin companies Airtel, Wipro, Tata, etc.

- Lean is an easy process; no formal training is required, especially to implement this in the organization. But as far as six sigma is concerned, it is a little bit challenging, and might be a formal lecture or training is required for the staff to understand it.

- Being as the operative tools in the company, these two are working for quality management but with different approaches.

- If these two are differentiated based on methodology, lean six sigma gets more marks than the six sigma because it somehow concentrates both on the qualitative and quantitative approaches.

Lean Six Sigma vs Six Sigma Comparison Table

Below is the 5 topmost comparison between Lean Six Sigma vs Six Sigma:

| Heads | Lean Six Sigma | Six Sigma |

| Meaning | This is methodical to remove the waste from the production. | This is the process of maintaining the quality of the product. |

| Problems | This process is difficult to understand, effective training is required. | Implementation of these rules is quite a challenging task, so supervision is mandatory. |

| Focus | It focuses mainly on how to waste management. | It focuses on how to enhance the quality of the product. |

| Profounded | This comes into existence in 1990. | This comes into existence in 1980. |

| Usage | To improve the efficiency of the manufacturing plant. | To improve the quality of the product being manufactured in the industry. |

Conclusion

By and then, it is confirmed that these two principles are very useful for production because quality and quantity is mattered a lot for every manufacturing unit. The usage or application of these two methods results in better output, which may result from waste reduction and quality management. So these methodologies are really very important for each and every company for the smooth working and also for profit maximization. The other thing that is very important to discuss here is the evaluation of the techniques because merely implementation is not sufficient; from time to time, an evaluation that what is the achievement and what more is required is also much necessary after a period of time.

The intellectuals in this field should also work on the enhancement of these two methodologies and should improve and add some more realistic principles in these two so that management and working become more easy and simple. The scientific principles of Taylor are needed to be discussed again so that more emphasis should be given to quality and productivity. At last, only one hope is there that upcoming versions of the quality control and waster control principles should be in the interest of employees who are the actual players to implement these in the organization and also a suitable guidance manual and training is like an extra feather in the cap, Early Kudos! To the development team.

Recommended Articles

This has been a guide to the top difference between Lean Six Sigma vs Six Sigma. Here we also discuss the Lean Six Sigma vs Six Sigma key differences with infographics and a comparison table. You may also have a look at the following articles to learn more –