Updated May 26, 2023

Principles of Lean Six Sigma

Today’s globalized dynamic environment demands high competitiveness and is digitally influenced for the potentially sustainable growth of the company. So this competitive edge necessitates following management approaches to instigate performance or productivity. Lean Six Sigma is one of the management approaches successfully implemented across many sectors and industries, like information technology, telecommunication, FMCG, healthcare, service sector, finance, etc., to transmute processes to business management processes. Integrating lean and Six Sigma ensures exceptional improvement in performance, like employee engagement and commitment toward customer satisfaction. We will learn about the Principles Of Lean Six Sigma in this topic.

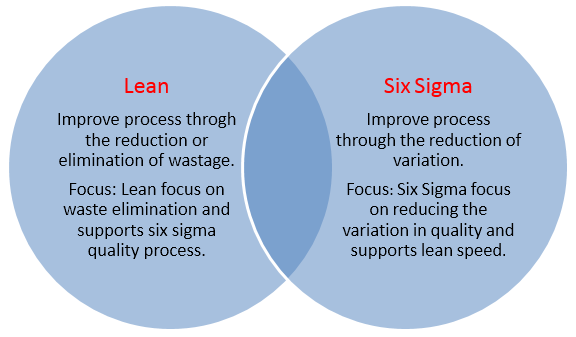

ASQ (American Society for Quality) states, “Lean Six Sigma is a fact-based, data-driven philosophy of improvement that values defect prevention over defect detection.” These two approaches have been combined to form an effective tool to enhance business processes. The lean principle focuses on reducing and eliminating waste, and Six Sigma emphasizes variation-reduction in waste.

What is Lean?

To assure sustainability in today’s unpredictable, rapidly changing economy, industries must reduce or minimize waste and maximize customer value. Lean is a systematic approach that removes wasteful steps in the process and takes only value-added steps, which will benefit streamline processes, lower manufacturing costs,s and reduce unnecessary waste. The wasteful steps like overproduction, defects of products or services, unprocessed inventory, extra processing, unrecognized talent, unnecessary transportation cost, long waiting for equipment, and unnecessary motion of personnel or tools, etc., enhance the cost of production, which leads to customer dissatisfaction due to the excessive price of ultimate product or service. That is why industries should practice a lean management approach that promotes continuous improvements.

It aids in

- improving product or service delivery time.

- Reducing the chance of defect.

- Reducing process cycle time.

- Optimizing key improvements

- reducing the wastage of inventory.

Some essential tools of the lean approach are VSM (value stream mapping), Kaizen (Continuous improvement), Kanban, Gemba (Go & See), JIT(Just in Time), Poke Yoke, etc., which industries may use for the elimination of wastage.

What is Six Sigma?

Six Sigma helps to improve the end quality of products ensuring minimum quality variation. It is a statistical quality control (SQC) method and a data-driven problem-solving methodology that ensures 3.4 defects per million output units. Six Sigma is also defined as a measurement of process performance with continually striving to reach the ultimate goal of Six Sigma by reducing the defects in quality control.

| Sigma Level | Defects per million | Yield |

| 6 | 3.4 | 99.99966% |

| 5 | 230 | 99.977% |

| 4 | 6210 | 99.38% |

| 3 | 66,800 | 93.32% |

| 2 | 308,000 | 69.15% |

| 1 | 690,000 | 30.85% |

Two kinds of statistical methods advance quality levels by reducing variability. These methods are – DMAIC ( D- Define, M- Measure, A- Analyze, I- Improve, C- Control) and DMADV (D- Define, M- Measure, A- Analyze, D- Design, V- Verify). The Six Sigma DMAIC approach is used for the existing process; however, when designing a new process, DMADV is used.

Principles of Lean Six Sigma Methodology

Every business leader optimizes a streamlined workflow and eliminates unnecessary or repetitive tasks to execute the workflow efficiently and effectively. Combining Six Sigma’s lean philosophy and statistical approach to reduce waste and variation of quality control.

The following principles of lean Six Sigma (LSS) can produce the best result.

1. Focus on Customer: One of the most prudent business advice from experts is that customer satisfaction is the ultimate goal of any business. A business can improve its product or service quality by prioritizing customers’ needs. After all, everything revolves around customer opinions. Before implementing any drastic or minor changes in a product or service, the primary goal is to establish and maintain quality standards that the market or customer demands.

2. Figure out the root cause: It is essential to figure out the root cause for the complete realization of the actual working process. To achieve this

- Business leaders must clearly understand the reason for data collection and what kind of data will be collected.

- Establish a standardized data collection system.

- Ensure accurate communication.

- Ensure an accurate measurement system.

After data collection, it is the primary work to determine whether the data will meet the goal or need to be changed. If required, the data should be improved to optimize the process by focusing on the root cause with a slight (incremental) variation.

3. Eliminate variation: After detecting the root cause of variation, it’s time to find ways to eliminate it, which is only trash in the process. The business manager must be very proactive in identifying the variation and promptly eliminate it. Streamlining or eradicating those variations is the ultimate way to make the process waste-free and effective.

4. Teamwork: The business leaders and team members must know about lean six sigma processes. The team members must be trained in Six Sigma’s methods, including measurement and improvement tools. In addition, each team member should enhance his or her communication skill to serve or communicate efficiently with customers and coworkers.

5. Create a culture of flexibility and responsiveness: Lean Six Sigma (LSS) always demands to accept positive change. That is why any kind of change in process should be communicated clearly among the employees at the beginning and even motivate them to receive the change professionally.

To cling with any faulty or inefficient process or function is not acceptable in LSS; However, sometimes managing a change in the processor becomes challenging, yet we must refine or remove the faulty one before its faults become obvious.

Therefore, we can encapsulate that the integrated approach of lean six sigma aids in improving process efficiency, elevating the utilization of resources, enhancing customer satisfaction significantly with the improvement of increased profit, and curtailing costs. Both the improvement and processes go hand in hand to implicate the improvement of existing methods.

Recommended Articles

This has been a guide to Lean Six Sigma Principles. Here we have discussed the Principles of Lean Six Sigma Methodology. You can also go through our other suggested articles to learn more –