Updated May 24, 2023

Introduction to Six Sigma Belts

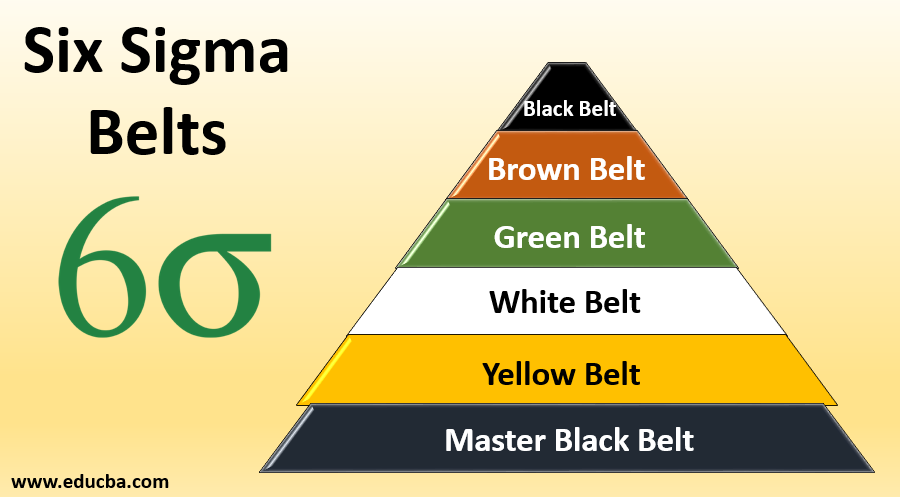

The following article provides an outline for Six Sigma Belts. Six Sigma is widely regarded as one of the top technical tools employed to enhance the quality of services and products. Six Sigma management systems focus on improving the business through improved management techniques. It is the most focused and rigorous for implementing the best principles and techniques for improved products and services.

This process works by analyzing the root cause of the problem and then works accordingly for the solutions to provide the best results. Eventually, six Sigma is putting more focus on reducing waste, improving quality, and producing better products and services faster and cheaper to provide growth to the organization and the customer. Six Sigma has a different approach based on the level of competence in understanding and applying related tools. Belts are the Green belt, Black belt, and Master black belt.

Features of Six Sigma

- Its focus and aim are to eliminate unwanted waste from the process and deliver the product and service whatever the customer is expecting.

- The structured, data-driven process followed by the participants prioritizes accurate data collection and analysis while defining their respective roles.

- Six Sigma is acknowledged for its multidimensional and structured approach, which significantly impacts financial statements. It aims to achieve increased profits, enhance customer satisfaction, and improve processes by reducing costs, minimizing process variability, and lowering defects.

Six Sigma Belts – Functionality Project

The functionality is defined into belts based on the complexity of the project.

#1. Black Belt

- Black belt emphasizes application and analysis. A black belt requires the highest level of understanding and an experienced person to work on it; The person responsible for implementing this method should possess the highest skill level, expertise, and experience in various techniques. The engineer designated to work for the black belt should have completed the thorough internal training program with experience working on several projects.

- The project assigns an experienced person to the team leader role to guide and lead the project to its goal, ensuring customer satisfaction. The technical experts are temporary for project-based, and full-time agents will return to other duties after completing a black belt tour. The key to the success of black belt Six Sigma is that the individual project leaders are assigned and responsible for making a project successful; it worked well for several projects. It is selected to work on business process improvement.

- Six Sigma works for the successful completion of high-impact projects that result in tangible benefits to the enterprise. Six Sigma black belt demonstrates a higher satisfaction rate. This is also one of the approaches for internal improvement consultants for the functional area.

#2. Master Black Belt

- The main purpose of a Master Black Belt is to have a deep understanding of applications and the statistical theory behind those applications. Master black belt trains other belts for better results, leading to project review. The person appointed to lead the team on this belt is the team leader, the team works under his leadership, but he can or cannot be a direct member of the group itself. We can liken this role to that of a coach for certain teams, as the individual brings experience and a comprehensive understanding of the technical aspects involved in complex projects.

- The Master Black Belt is proficiently equipped to handle procedural inquiries and resolve technical issues. The Master Black Belt in Six Sigma is guided by a Six Sigma expert who holds a Black Belt certification and additional specialized skills or experience in implementing Six Sigma methodologies throughout the organization. By using a master black belt, the project can be highly proficient by using the six sigma methodology to achieve tangible business results.

- An advanced understanding of analyzing statistical data, project management, communication, program administration, teaching, and project coaching is a must for a master black belt other than black belts. This also identifies high-leverage opportunities for applying the six sigma approach; it includes black belt training, green belt training, coach mentor black belts, and ACME six sigma participation to certify black belt and green belt.

#3. Green Belt

- These are essential analytical tools, and they work for less complex instruments. The green belt designation can belong to the team leader or team member and work directly with the team leader. This can be led by less experienced other than black belts. It just needs a better casting of the team leader. A green belt is for smaller and more manageable projects, not considered for complex projects.

- The elected leader can be a part-time leader for the project rest; he will perform daily duties as assigned. It must demonstrate the mystery of the green belt body of knowledge and demonstrate quality at achieving better results. Green belt people participate in improvement. Green belt team members work with leaders of black belts for improvement with data analysis. These trained members are eligible to teach local teams and share knowledge of Six Sigma. To maintain a six sigma certificate, the member should complete at least one six sigma project every 12 months. Green belt training is five days of classroom training with six sigma projects.

- The training includes project management, quality management, quality control tools, problem-solving, and descriptive data analysis topics. The expert in Six Sigma must attend green belt training; usually, six sigma black belt help green belt define their projects before training, so it will be beneficial to participate in green belt training and assist them afterward.

- Six Sigma team members are trained to apply six sigma tools to projects. They actively participate in team tasks and communicate well with other team members. Over the period, they gain the knowledge they use to demonstrate basic improvement tool knowledge and accept tteam’sm’s execution of assignments.

#4. White Belt

Those looking to learn the basics of Six Sigma consider this belt an introductory belt. This is the belt for learning if your company deploys lean six Sigma and its essential tools and concepts.

#5. Yellow Belt

Yellow Belt will prepare the person to work as a team member in the six sigma projects, providing the basics to enter the six sigma projects.

#6. Brown Belt

Six Sigma does not officially define this belt. Some organizations classify it as a green belt and pass the black belt certification exam, but a second six sigma project is pending.

Recommended Articles

This is a guide to Six Sigma Belts. Here we discuss the introduction, features, and Six Sigma Belts – functionality project. You can also go through our other suggested articles to learn more –