Updated June 9, 2023

Introduction to Six Sigma Concepts

Six Sigma concepts have been the initial framework, which includes various approaches, methodologies, and six sigma concepts lean tools for process improvement within a business. Six Sigma concepts hold a pivotal role in entire business strategies and prod the top management to get methods to produce more quality at every stage and step they undergo. The data processed drives it, follows the rules, and adopts a disciplined line of thought. Six Sigma guarantees less wastage and high-quality systems and processes for usage by groups and individuals. With Six Sigma concepts, defects are targeted and eliminated throughout the production line by comparing the point variation between the ideal or expected and the actual result/output from the product to its service.

On the other hand, we have Lean, primarily used in manufacturing but has gained precedence recently as the set of methodologies to eliminate waste in the curve and turn the production process.

Lean methodologies have processes as a “value stream.” Management of this value stream involves defining values in the product and process capabilities within a workflow. It focuses on the customer’s needs and ensures that customers receive the product or service they need at the right time and at the correct cost for purchase.

Here are a few differences between Six Sigma concepts and Lean:

| Six Sigma concepts | Lean |

| Focuses on the reduction of variation | Focuses on the removal of waste |

Follows the methodology of DMAIC:

|

Follows the step-by-step methodology:

|

| Focuses on the problem | Focuses on the Flow of processes |

| The effect is uniform process outputs | The effect is a reduction in the timing of the flow |

| For organizations stressing analytical studies. Use of high and low-level data, charts, and collaborative research. | For organizations looking at visual value change and stress at the right now time. |

| Sectors it caters to include manufacturing, logistics, data-driven businesses | Sectors it caters to include trade, healthcare, administrative |

Looking at the best of both worlds, professionals have repeatedly increased the chances of integrating the two galaxies of business methodologies into one. Concentrating on the pros between the two methods, combining the two systems gave rise to “Lean Six Sigma,” a pure cross-over between potentially alive methodologies for enhanced quality and leaner processes, thus, increasing company revenues and entailing products bearing high quality and shorter turnaround times.

Diving deeper into these methodologies, companies find it very beneficial to pick up the following five principles or approaches harnessed within the concept of Lean and integrate them into the higher-leveled Six Sigma concepts. The amalgamation has always brought to the front the enhanced quality produced by lean tools, Six Sigma, and optimum turnaround time by Lean. This, in turn, results in high-impacted, quick-hit projects in most of the sectors. Enlisted below, staying true to the scope of the article, are the 5 Lean principles or approaches that one integrates into Six Sigma concepts for efficient product/service processing:

Note: Become a Lean Consultant

Learn how to implement lean principles. Understand lean tools and techniques of lean manufacturing and total productive maintenance. Become a successful Lean consultant with our training.

5 Integrate Into Six Sigma Concepts

Following are 5 lean-to integrate into six sigma concepts.

1. Value Stream Mapping

At every stage of the process flow, the value is added, depreciated, or can be enabled. Value needs to be mapped for the project manager and the team to understand where the addition of the deal is missing. The unit can use this knowledge to eliminate such activities and significantly decrease the wait time between two process steps.

The benefits of this approach within Six Sigma concepts are as follows:

- Leaner Processes

- Reduction in Time

- Elimination of Waste

- Improved Results

This value stream mapping process can occur either in the Analyze or Improve phase of the DMAIC methodology, also within the Kaizen Cycle. Here, consider the flow of materials or information to map the workflow for that particular department or organization accurately. And hence, the three categories are born, segregating each activity step by step.

As mentioned above, the value-adding activities are enhanced, the non-value-adding activities are eliminated, and further segregation of the value-enabling activities into actions that can add value and those that would cost the company yet not add the necessary value the company is looking for.

Using the funnel approach to map value streams can benefit large and small teams effectively. The eliminations allow the processes to be compact and even help achieve the Six Sigma concepts principle of reduction in variation.

Example

An example that came from my own experience; on mapping the value stream for a said process, it came to light that a specific approval went to two different individuals within the workflow, who were basically following the same checklist for six sigma concepts quality checks but from a higher level it seemed to the business that the approvals were acting as filter and sub-filter. Once people knew that the second approval was not providing any value in the process, they soon decided to eliminate the workflow loop, which reduced the processing time by a workday.

It is precisely how value stream mapping can benefit a workflow and help enhance six sigma concepts’ quality and reduction in time.

2. Ishikawa (Fishbone) diagram and 5 Whys

Also known as the cause-and-effect diagram, Ishikawa is a tremendous lean tool for root cause identification and analysis. Within Ishikawa, the causes of the problem are graphically represented as bones of the fish, branching from the prominent bone, describing the event that has taken place.

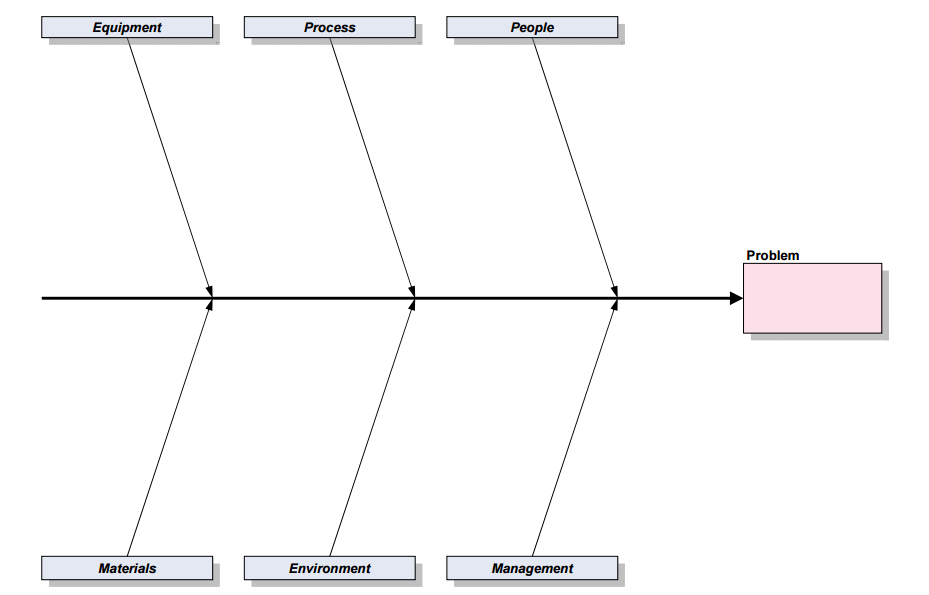

Ishikawa usually is used to efficiently structure a brainstorming session for a particular problem, event, or effect. The causes come into six categories for efficient use of the fishbone diagram; otherwise, straying away from the root cause is just as simple. These categories are as follows:

- Process

- People

- Equipment

- Materials

- Environment

- Systems

The diagrammatic representation of the Ishikawa is as follows:

Primary causes directly branch out of the fishbone categories, while secondary causes branch out of the primary reasons. This further branching enables reaching the root cause quicker.

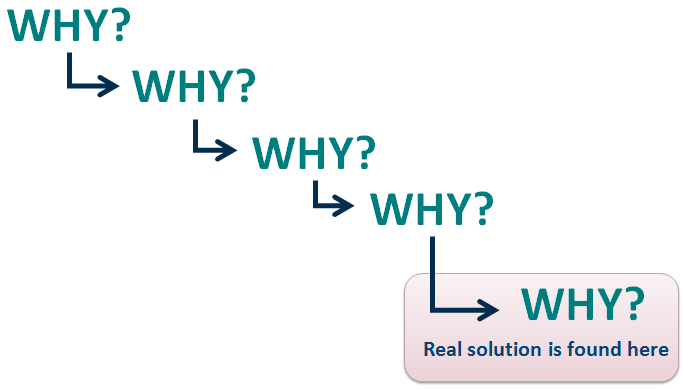

5 Whys, on the other hand, is as simple as asking the five whys to the problem and getting answers, thus, drilling down to the root cause of the issue. Typically clubbed with Ishikawa, 5 Whys is an effective lean tool for cause-and-effect analysis. Some problems require asking only 2 or 3 Whys before reaching the root cause, while others may require more than 5. Ideally, the identification of root causes occurs with the 5 Whys.

Even with the case of 5 Whys, brainstorming is essential, and a project manager would be steering the session should there be any diversion and the subject entirely lost.

Within Lean, there needs to be more focus on the visual representation of data not followed in Six Sigma concepts. But, Lean boasts of root cause lean analytical tools such as Ishikawa and 5 Whys to get to the root cause of problems without using statistical and concrete figurative data.

These methodologies take place in the Analyze phase of the Six Sigma quality framework. It makes managing Six Sigma concepts easy and simplified.

3. Takt Time

Derived from the German word, Taktzeit, which directly refers to the heartbeat or drumbeat of production in Lean lingo, Takt Time is the time taken from the start of the production process of a single unit until the beginning of the show for the next team in line. These differences are calculated and compared to the demand for the product or service coming directly from customers. Once matched, users compare them to decrease the deviation from the rate of customer demand.

When used with Six Sigma concepts, Takt Time is then used to analyze the potential and current loads and bottlenecks within production processes, thus, enabling project managers to accurately decipher what the time spent on each strategy and task is and providing opportunities for improvement in ways, whether the Takt Time exceeds the service level agreements (SLAs) or stays within the stipulated time.

This analysis is essential in capturing the overloading of tasks or even surplus capacity within certain production lines and making process flows easier and much leaner, ensuring minimum or negligible variation and defects. Hence, the deviation between Takt Time and customer demand, if excess, calls for thorough improvement in the said process/task.

Suppose the business comes across processes working faster than the customer demand. In that case, it can be beneficial for the organization to direct the time saved by this process into sharing the load from another method lagging back in its efforts to catch up with customer demand.

This implementation of the process can be during the Analyze phase.

Example

Suppose an organization has a Takt time of 10 minutes. In that case, it translates to having a product or service’s production process completed off the line because, on average, the product/service sells to the customers at 10 minutes per unit.

4. Heijunka

Comes from the Japanese word translating to “leveling,” Heijunka is the lean tool that helps in load balancing across the value stream of the production process it is being implemented into. This principle and lean tools are implemented in the Design phase within Six Sigma quality after the root cause analysis points out the bottlenecks in the Analyze phase. The working of load balancing introduces a “Pull” in the system that is unlike the traditional “Push,” which results in overloading, side loading, and bottlenecks within the process.

Takt time can be critical in implementing Heijunka within Six Sigma quality, as it will lay out the entire value stream with the time taken within processes.

Earlier in traditional production lines, batching was the sought-after process method for mass producers of any material or product. With the inclusion of Lean within systems and organizations, there was some disapproval of the method of Batching for the following reason:

“According to Heijunka, production systems cannot by design and load continuously respond to orders without suffering from a certain ” mura” (unevenness in quality rendered and productivity achieved) and “muri” (overburdening of machines, workforce). The product of mura and muri is “muda,” which is waste.”

5. Poka-yoke

A fine-tuning lean tool for Lean, Poka-Yoke is a mistake-proofing thin tool that drastically reduces the probability of errors within sectors of the workflow. Lean tools Six Sigma One can effectively utilize These lean tools in the Design and the Improve phases of Six Sigma quality. At these stages, it can dramatically help improve or completely redesign systems to reduce or eradicate errors within the workflow. In specific industries, companies combine Poka-Yoke with DMADV (Define-Measure-Analyze-Design-Verify) to actively identify the probability of mistakes resurfacing during live stages.

An amalgamation of Poka-Yoke along with Ishikawa and Pareto Analysis can give the business staggering results in root cause identification and elimination of defects and errors, thus, fulfilling the purpose of Six Sigma quality very efficiently.

Chipping off the edges to a smooth finish is what is needed at the later stages of the six sigma quality project once the software/product is developed and ready for review. Poka-Yoke, at this point, comes in as beneficial for polishing the product to eliminate any discrepancies or fallbacks.

Example

A famous example used to illustrate the use of Poka-Yoke is when there was an abrupt termination of many workflows in a payroll system. On application of root cause analysis, it found that there were two buttons with misleading labels present on them. One read, “Approve to Next,” meant the approval of step, and the workflow prods forward, while the next read, “Approve to Close,” said the approval of action and the workflow closed here. The terminology used was somewhat misleading and was the cause of the abrupt terminations; hence, with Poka-Yoke, users fine-tuned the process and now introduced the lean tip tools to explain the buttons further.

Getting together the giants of the production and business world can be daunting, but it can be as productive and qualitative as well. Lean’sLean’s integration with Six Sigma quality gave the world a finer and more improved methodology to look up to for any sector in many industries and businesses.

If you liked this article and found it helpful, click on the Like and Share buttons to let your peers know more about Lean Six Sigma quality. Keep reading our blogs for such exciting articles.

Recommended Articles

This has been a guide to Lean tools Six Sigma Concepts. Here we have discussed basic concepts and 5 Lean Tools to Integrate Into Six Sigma Concepts. You may look at the following articles to learn more –