Introduction to Six Sigma Model

Six Sigma is the technique or principles for quality improvement in the industry. These principles were initially introduced by Motorola in 1980. Every company, industry which Focuses mainly on quality and improvement in the process uses this very method or principles of Six Sigma. Quality control is the prime task in every industry because every industry wants huge profits by utilizing fewer resources, and this is only possible when there is a set procedure of work. Here the six sigma came in seen; initially, these principles are not properly used in the industries because it demands proper implementation and high skills. But with the change in time and competition in the market, every company start implementing this set of principles to make their product quality good. So now we will discuss the full model of the Six Sigma principles and see how it works and is implemented.

Methodologies of Six Sigma Model

Given below are the methodologies of Six Sigma model:

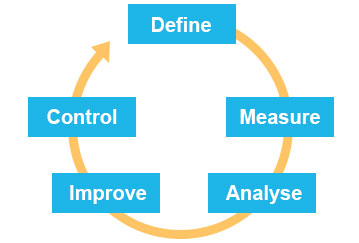

1. DMAIC

This is one of the methods of six sigma principles, and it is used for quality improvement and problem eradication in the different processes.

It consists of 5 things, or we can say it is the abbreviation of:

DEFINE, MEASURE, ANALYSE, IMPROVE, CONTROL.

Diagram:

- Define: It is the first phase of this method, in which the whole project is discussed holistically, and every single detail is defined properly so that there is no scope of fault during the process. Also, the focus is on the problems which may occur during the process, and the solution of these problems is also discussed.

- Measure: It is one of the main steps of the method because, in this process, the whole raw data is collected and synthesized, and then it is measured with statistical methods so that accurate information will be provided to the employees and to the system.

- Analyze: This is the next step after the collection of data; in this very step whole process and data are analyzed, and the root cause of the different problems is conceptualized. By and large, this is the investigation type of method which is quite important and also very necessary.

- Improve: After all these steps, the next step, which is the hard step, is to improvise the project. This is a very comprehensive step because when data is collected and analyzed the improvisation is very important so that if there is any defect in the whole project or any defect found amid of process, it will be corrected in due course.

- Control: The last step of this method is the control of the whole process so that the project will be completed on time and also the resources and time it will be saved. Also, the control process is highly important to make the project result-oriented and to make employees concentrated.

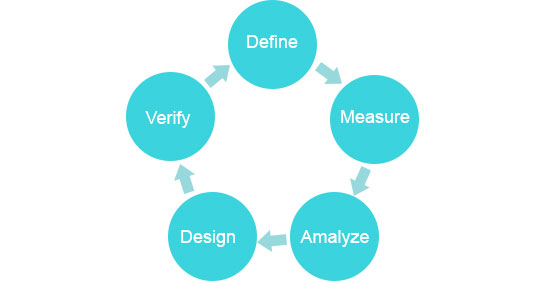

2. DMADV

The next method of the six sigma is the DMADV, which is also very significant and means a lot in different processes of the industries.

It is the abbreviation of:

Define, Measure, Analyze, Design, verify.

Diagram:

- Define: In the first step of this methodology, the goal is defined, and the target is assigned. The whole tactics are illustrated prior so that the project runs smoothly. The main focus of this process is to put the project on track.

- Measure: Measurement is the important step in this method; in this different type of technique is used to measure the progress of the work, and mathematical and statistical methods are used to find out the exact values for the process.

- Analyze: Analyze technique is used to find the progress and evaluation of the project. In this very method, every single step and goals are analyzed properly to match them with the predefined criteria so that the whole project will stay online and conclude properly.

- Design: In the design method, the final result is defined. The whole project is synthesized, and extra data is removed, and the problem which is occurred is mitigated. The design process is an essential step in the whole process of this methodology. Also, the managerial focus on this step because total team output is reflected in this very step.

- Verify: The last step of the whole process is the verification of the whole project so that the final touch is given to the project before submission. Verification is also necessary because if any problem occurs, it will remove on time, and it will not impact the performance of the whole project.

Tools Used in Six Sigma

These methods are used by various tools, which have different approaches, but the result is the same.

So here are some tools:

- Anova

- Scatter Diagram

- Chi-Square Test

- Cost-Benefit Analysis

- Enterprise Feedback Management

Applications of Six Sigma

Six Sigma is used in various fields, and it is a quite important method or tool, so here are some fields in which the method is used:

- Manufacturing

- Finance

- Engineering

- Construction

- Supply Chain

Conclusion

Six Sigma Model has prevailed now in every type of industries and management is quite interested in these principles because of several reasons like quality is managed, less burden on resources, higher employee involvement. So every industry or other company is really focused on introducing these principles in their respective firms. Apart from that, six sigma principles are employee-centric and demand proper implementation for which high skills are required like managerial as well as leadership qualities.

This is also true that some firms are used to lean the six sigma principle despite six sigma because it is more work-centric. As the trend changes day by day new type of technologies and machinery is introduced in the industries and to make employee comfortable with these new technologies six sigma may play an important role ahead. Also, it remains to be seen that what is in the blanket of the future because the six sigma model is also very old, and industries are now demanding a new type of principles to fulfill the new needs of the industries. I hope thinkers and intellectuals will find a concrete solution to this problem very soon.

Recommended Articles

This has been a guide to Six Sigma Model. Here we discuss the methodologies, tools, and application of six sigma respectively. You may also look at the following article to learn more –