Spring-Loaded Pins

Spring-loaded pins are essential for electrical connections, ensuring reliable contact in various applications, from consumer electronics to industrial machinery. Promax, a trusted name in precision engineering, offers high-quality spring-loaded pins designed for reliable electrical connections across various applications. These Promax spring loaded pins are engineered for durability, versatility, and consistent performance, making them the ideal choice for industries that require dependable electrical contact solutions.

What Are Spring-Loaded Pins?

Spring-loaded pins, also known as pogo pins, are mechanical connectors designed to provide consistent electrical contact. They use a built-in spring mechanism to adjust to changes in alignment and positioning, ensuring a strong and reliable connection between two surfaces.

Key Components

It consists of four main parts:

- Pin: The conductive element that transmits electricity. The pin’s size, shape, and material vary based on application needs.

- Spring: Applies the right amount of force to stay in contact, adapting to pressure changes.

- Housing: Holds the pin and spring in place, ensuring proper function.

- Electrical Contacts: The surface the pin interacts with to complete the electrical circuit. These contacts are often coated with gold or nickel to enhance conductivity and prevent corrosion.

How Do Spring-Loaded Pins Work?

The operation of spring-loaded pins is simple yet effective. When pressure is applied, the spring compresses, allowing the pin to make contact with an electrical surface. This engagement establishes a reliable connection, preventing signal loss and ensuring continuous electrical flow. Once the pressure is removed, the spring pushes the pin back to its original position, maintaining the integrity of the connection.

This mechanism allows for consistent performance, even in applications where slight misalignments occur during assembly or operation.

Types

Here are the most common types:

- Standard Pogo Pins: They are used in smartphones and tablets to charge and transfer data.

- High-Current Pins: Designed for applications requiring the transmission of high electrical currents, such as battery connectors.

- Miniature Pins: Used in compact devices where space is limited but reliable connectivity is essential.

- Sealed Pins: Built to withstand harsh environments by preventing dust and moisture from affecting performance.

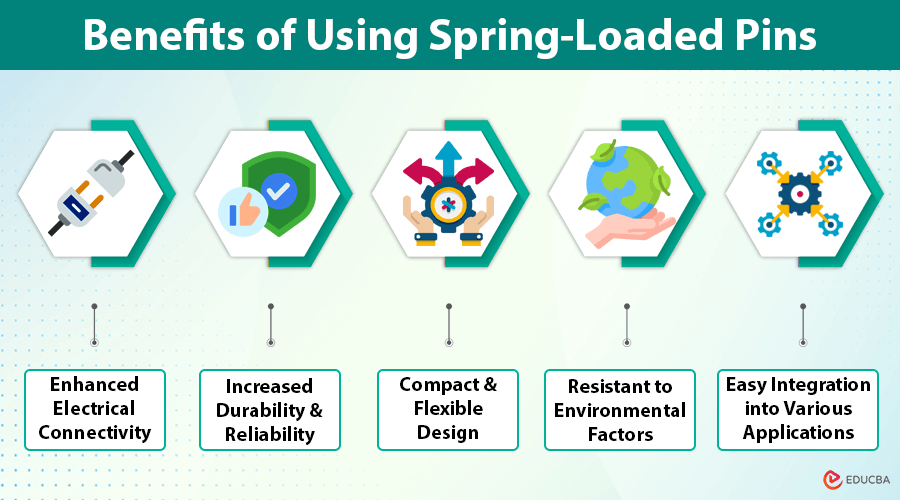

Benefits of Using Spring-Loaded Pins

It offers several advantages that make it a preferred choice for electrical connections:

1. Enhanced Electrical Connectivity

It provides stable and consistent contact, reducing signal loss and ensuring smooth data transmission. Their spring mechanism adapts to movement and alignment changes, maintaining uninterrupted connectivity.

2. Increased Durability and Reliability

Due to their robust design, spring-loaded pins can withstand repeated use without degradation. The materials used, such as gold-plated contacts, help resist corrosion and wear, extending the lifespan of devices.

3. Compact and Flexible Design

They are small in size, allowing them to fit into compact electronic devices without sacrificing performance. Their flexible design makes them ideal for applications requiring quick and secure connections.

4. Resistant to Environmental Factors

Certain types of spring-loaded pins, such as sealed variants, are resistant to dust, moisture, and extreme temperatures. This makes them perfect for industrial and automotive applications where environmental exposure is a concern.

5. Easy Integration into Various Applications

They are easy to incorporate into various designs, offering a plug-and-play solution for electrical connectivity. This reduces assembly time and enhances overall efficiency.

Applications of Spring-Loaded Pins

Some of the key applications include:

1. Consumer Electronics

Spring-loaded pins are essential in smartphones, tablets, and wearable devices. They provide stable connections for charging ports, docking stations, and data transfer points, ensuring a seamless user experience.

2. Automotive Industry

In the automotive sector, spring-loaded pins play a critical role in connecting various sensors, control units, and battery terminals. Their ability to withstand vibration and temperature fluctuations makes them ideal for vehicle applications.

3. Industrial Machinery

Spring-loaded pins are used in heavy-duty machinery to establish reliable electrical connections in automated systems and robotic assemblies. Their durability ensures smooth operation even in demanding environments.

4. Medical Devices

Medical equipment relies on high-precision electrical connections for functionality and safety. It maintains accuracy and efficiency in diagnostic tools, wearable health devices, and communication ports.

Final Thoughts

Spring-loaded pins are an essential component in modern electrical connections, offering reliability, durability, and adaptability. Their ability to maintain strong contact despite misalignment or movement makes them ideal for consumer electronics, automotive, industrial, and medical applications.

By choosing the right type, engineers and designers can enhance efficiency, reduce signal loss, and improve the longevity of their devices. As technology advances, the demand for high-quality electrical connections will continue to grow, solidifying the role of spring-loaded pins in the industry.

Whether in small wearable devices or heavy-duty industrial machinery, spring-loaded pins remain a key factor in ensuring consistent electrical performance and connectivity.

Recommended Articles

We hope this guide has been helpful. Check out these recommended articles for more insights on electrical connectors, precision engineering, and innovative design solutions.