Updated December 14, 2023

Stock-Taking Meaning

Stock-taking is when companies count the quantity of goods they have by hand. It ensures that their inventory, as per records and actual available stock, is equal and accurate.

The goal is to identify any discrepancies in the inventory records. It ensures there’s no overstocking or understocking and detects any theft or shrinkage. Businesses perform stock-taking periodically to maintain inventory control and facilitate better decision-making regarding inventory management.

Table of Contents

Key Highlights

- Stock-taking is the process of tracking the actual inventory against the recorded inventory to ensure accuracy.

- It helps identify theft or damage, maintain optimal stock levels, ensure compliance, and facilitate audits.

- This process involves planning, preparation, counting, recording, verification, analysis, adjustment, and reporting.

- Common methods include periodic, annual, spot, or line checks, stock-out validation, perpetual, ad-hoc, cycle counting, and ABC analysis.

Purpose

Stock-taking verifies if the actual physical quantities of items on hand match the recorded figures in the inventory system. It also identifies any instances of theft, shrinkage, or damage to inventory items, enabling businesses to take corrective actions and enhance security measures.

Companies can prevent understocking and overstocking and maintain an optimal stock level. It facilitates better decision-making regarding purchasing, sales, and production.

Apart from that, the data gathered is also useful for financial reporting purposes, such as preparing financial statements and tax calculations. It also helps firms ensure compliance with regulatory requirements and provide necessary information for internal and external audits.

Procedure

The stock-taking procedure involves the following steps:

- Start with deciding the timing, frequency, and method, and allocate the required resources for the process.

- Organize the workspace in a way that gives you access to all inventory areas.

- Gather necessary tools like counting sheets, barcode scanners, or software systems.

- Begin the physical counting process. Use a systematic approach, either by counting sections or all items.

- Ensure accuracy in quantity, description, and location while documenting the counted items in the system.

- Note any discrepancies, damaged goods, or irregularities observed during the counting process.

- Cross-check the counted inventory against the recorded figures in the inventory management system to identify differences or discrepancies.

- Investigate any discrepancies found and determine the reasons behind them. It involves rechecking, investigating possible errors, or conducting recounts if necessary.

- Update the inventory system or records to match the accurate physical stock count.

- Generate reports summarizing the stock-taking results, including any discrepancies, adjustments, and recommendations for improving inventory management practices.

Methods

Different businesses can use different types of stock-taking methods depending on factors like the size of the business, inventory turnover, etc. Some of the most common methods are as follows:

1. Periodic Stock-taking

It involves physically counting the entire inventory at scheduled intervals, such as monthly or quarterly. It is usually suitable for small businesses with manageable stock because they need to pause operations to physically count all items in stock temporarily.

2. Annual Stock-taking

It is similar to the previous method, the only difference being that it’s performed only once a year. Annual stock-takes usually happen towards the end of the year. Mid-sized businesses with relatively stable inventory turnover use this method to assess their stock levels.

3. Spot or Line Checks

Unlike the other methods, spot checks involve random counting of specific sections or items in the inventory. Spot checks also happen regularly throughout the year. However, it doesn’t involve counting the entire inventory. This method suits larger businesses, warehouses, or distribution centers. It helps in the ongoing monitoring of inventory accuracy without disrupting overall operations.

4. Stock-Out Validation

This method verifies inventory records when items are sold out or unavailable for purchase. Retail stores frequently use this method to reconcile their recorded inventory levels with what’s physically present on shelves. The purpose of stock-out validation is to ensure the records align with the actual availability of products for sale.

5. Perpetual or Continuous Stock-taking

This method continuously tracks inventory levels through technology such as barcode scanners for inventory management software. Larger retail stores, warehouses, or businesses with high stock turnover commonly utilize this method. It provides real-time stock information without the need for complete shutdowns.

6. Ad-hoc Stock-taking

This method refers to a physical inventory or stock count performed at irregular intervals rather than at regularly scheduled times. It can be for various reasons, such as sudden discrepancies, suspected errors, an upcoming audit, or unexplained issues in their inventory. This method quickly addresses and rectifies any discrepancies in stock records.

7. Cycle Counting

This method involves dividing the inventory into smaller sections or categories and regularly counting a portion of the inventory, typically throughout the year. It’s an ongoing process that allows for more frequent checks on high-value or fast-moving items while minimizing disruptions to daily operations.

8. ABC Analysis

Like cycle counting, ABC analysis also involves dividing the inventory into smaller categories. However, in ABC analysis, the categorization is based on the inventory’s value or significance. Typically, items are classified into three categories: A (high-value items), B (moderate value), and C (low-value). Businesses usually count high-value items more frequently, while low-value items are counted less frequently.

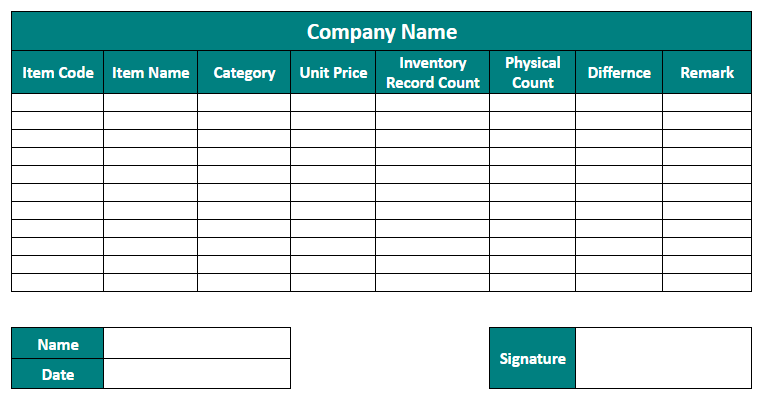

Format

The stock-taking format is the structured layout or arrangement that businesses use to record the inventory counting process. It helps ensure consistency and accuracy in recording inventory levels. Although the format varies from one business to another, it should include all the details necessary for accurately capturing inventory information during the stock-taking process.

Format Includes:

- Item Description: Details or descriptions of each inventory item or product, such as name, code, manufacturer, category, price per unit, etc.

- Quantity: The actual quantity of each item physically counted during the stock-taking process, as well as mentioned in the inventory records.

- Location (Optional): Where each item is stored within the warehouse or store.

- Unit of Measurement (Optional): The unit used to measure the quantity of each item (e.g., pieces, kilograms, liters).

- Value (Optional): The value assigned to the inventory. It is often calculated based on the quantity counted and the unit cost of each item.

- Discrepancies: Any differences observed between the physical count and the recorded inventory levels, including overages or shortages.

- Remarks or Notes: Additional comments or observations relevant to specific items or the process, such as damaged goods or special circumstances affecting inventory accuracy.

Format Template:

Examples

Following are some of the examples of stock-taking.

Example #1:

Suppose you run a retail store selling groceries. A customer asks you for 10 kg of flour from a particular brand. You quickly check in your system to see if the item is available, and the system says it is. You pick it up and find out the item isn’t available.

You conduct a spot-check in the flour section using a barcode scanner. Your spot-check reveals that the system indicates 5 units in stock, but there are none. You record the discrepancy in your inventory management system and discover what went wrong.

Upon investigating, you find out it happened due to a data-entry error during shipping. You correct the mistake in the system and place an urgent order for the item.

Example #2:

Imagine you run a large distribution warehouse that stores different types of products. Since there are a lot of products in large quantities, you decide to implement the cycle counting method. You start by dividing the warehouse inventory into manageable sections or zones like Zone A, B, and so on.

Each week, they target a specific zone for stock-taking while other sections continue regular operations. For instance, in Week 1, the inventory team focuses on Zone A. They use a barcode scanner to count all items in this section. Throughout the week, the team meticulously counts, verifies, and reconciles the quantities in Zone A. Once they complete the count in Zone A and make any necessary adjustments to inventory records, they move on to the next Zone.

This systematic cycle stock-taking approach enables the warehouse to continuously monitor inventory accuracy across various sections without interrupting overall warehouse operations.

Importance

Stock-taking is essential because by conducting regular stocktakes, businesses can accurately report their inventory levels and value on financial statements. It is important for tax and accounting purposes. Accurate inventory data also enables businesses to make informed purchasing, sales, and pricing decisions. It helps avoid overstocking of slow-moving items while ensuring sufficient stock of high-demand products.

On the other hand, it helps identify discrepancies between recorded and actual stock levels, uncovering errors, theft, or damage. This early detection prevents further losses and enables businesses to take corrective measures promptly.

Accurate inventory management ensures that products are available for customers as and when needed. It, in turn, leads to better customer satisfaction. Furthermore, proper stock-taking ensures compliance with regulatory requirements and provides necessary information for internal and external audits.

Final Thoughts

Stock-taking is an essential process for any business that holds inventory. It helps businesses maintain control over their inventory and make informed decisions about their operations.

Frequently Asked Questions (FAQs)

Q1. What is the difference between Stock-taking and inventory management?

Answer: While stock-taking is the process of physically counting inventory levels, inventory management includes planning, organizing, and overseeing the procurement, storage, tracking, and utilization of inventory throughout its lifecycle.

Q2. Who is responsible for stock-taking?

Answer: The responsibility for stock-taking typically falls on the inventory management or operations team within a business. Specific roles and individuals involved can vary based on the organization’s structure and size.

Q3. Can Stock-taking be done using a computerized system?

Answer: Yes, many businesses use computerized systems, such as barcoding or RFID, to track their inventory.

Recommended Articles

The above article on stock-taking is comprehensively written by EDUCBA. If you found the article useful, we recommend reading the following related articles: