Updated May 30, 2023

Introduction

‘Total Quality Management, often abbreviated as ‘TQM,’’ is the practice introduced by a famous American management consultant, William Deming, who greatly influenced Japanese manufacturing. In this article, we will discuss Total Quality Management Benefits.

“Quality is never an accident. It is always the result of an intelligent effort”.

-John Ruskin

Definition of Total Quality Management

A continual process of improving and enhancing customer satisfaction through a comprehensive approach of management by ensuring the participation of all the employees to deliver superior quality of product or service for long-term success.

Why would a customer buy your product or service if your competitors offer the same? The variant happens to be ‘superior quality.’ ‘Quality,’ a determining factor, which outstands a product or service from its competitors, plays a crucial role in business. Therefore, TQM focuses on customer satisfaction and aims to improve the processes, organizational culture, and systems by engaging every single employee to bring long-term success.

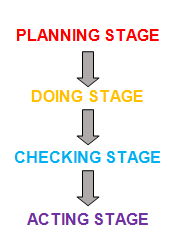

The Cycle of ‘TQM’

The cycle of TQM is divided into 4 phases, popularly referred to as the ‘Deming cycle’ or ‘PDCA cycle.’ Let’s briefly understand these stages:

- Planning Stage: The primary stage in TQM requires employees to identify the undergoing problems, issues, or any challenges with the organization’s operations. Employees have to revise the hypothesis and conduct necessary research by collecting data to test the same and come up with recommendations for a problem.

- Doing Stage: In this stage, employees design solutions for identified problems and implement strategies to overcome them same. The effectiveness of the results is also measured in this phase.

- Checking Stage: The comparative analysis of the attained results/data before and after conducting the research are measured.

- Acting Stage: The last stage is where derived solutions/recommendations are implemented.

What are the Benefits of Total Quality Management?

Some of the Benefits of Total Quality Management are:

1. Cost Reduction and Increased Profitability

TQM helps in reducing total quality costs. It is based on the principle of preventing defective products/services rather than being at the expense of quality failure cost. So basically, it aims to manufacture zero-defect products/services. Consequently, this brings in cost reduction and thus increased profitability. Companies such as Toyota Motors and Motorola have bought into manufacturing cost reductions by implementing TQM techniques.

2. Facilitates productivity

Cost reduction is a means of increased productivity. Productivity implies maximum output with optimum utilization of resources. Thus, superior resources, infrastructure, high-end technology, and competent employees enhance productivity.

3. Reduces Redundant Activities

TQM applies a systematic approach by assigning quality improvement teams to reduce unessential tasks and waste of resources, thus, bringing in efficiency. This also saves time and duplication of tasks.

4. Promotes Innovation Process

TQM enables organizations to research any undergoing challenges/ problems to come up with solutions for the same. Thus, organizations escalate their research and bring in innovative marketing decisions. The implemented innovative approach to the core and peripheral services attracts customers.

5. Market-Specific Products/Services

Since the main focus of TQM is on customer satisfaction, it provides a pathway to understand the needs and demands of the consumer market. Therefore, it enables the organization to deliver products/services specific to the market.

6. Holistic Approach to Management

Many organizations struggle with a non-engaging and non-participative attitude of the employees. TQM enables changes in the employees’ behavioral patterns by facilitating good work culture, and teamwork, promoting self-development and employee engagement, and thus extracting better performance.

7. Promotes Continual Improvement

The basic fundamental of TQM is continually improving for long-term success. Therefore, TQM practices are designed to enhance the quality standards of a product/service constantly. This results in a continuous revival of processes.

8. Facilitates Competitive Edge

The increasing competition challenges the organization to meet the ever-increasing consumer market demands. TQM practices help understand the market trends and competition to develop effective strategies to overcome the same.

9. Promotes Goodwill

As TQM focuses on consistently delivering good quality products/services, the consumers hold a favorable reputation for the organization. The internal stakeholders (employees and investors) get lucrative incentives and good returns, respectively, while external stakeholders (customers) get superior quality goods. This results in a good brand image and goodwill in the long run.

10. Facilitates Effective Communication and Employee Morale

Often, improper and ineffective communication hinders an organization’s proper functioning and development. This results in improper understanding, low productivity, inferior quality, and wasted time and effort, thus contributing to low morale. Whereas TQM facilitates effective communication and interaction among members of different departments and hierarchies of management. This boosts employee morale and teamwork.

11. Facilitates Customer Satisfaction

Since TQM is all about delivering a superior quality of products/services to the customers in the long run, customer complaints are quite less. Therefore, it signifies less use of resources and increased customer satisfaction. Thus, the market share also increases as the existing customers act as ambassadors to attract new customers.

Therefore, it is evident that TQM brings tangible results like superior product quality, reduction in costs, increased profitability, increased market share, and productivity. But, intangible returns like better communication, teamwork, employee engagement, customer satisfaction, goodwill, and increased employee morale. However, TQM also requires employees to undergo a substantial duration of training period, company-wide involvement, and participation in quality improvement. All levels of the organizational hierarchy must be involved to make the TQM program successful. However, any short-coming in the efforts or improper utilization of resources could make the success of the TQM program doubtful and collapse the internal bonding of the company. TQM techniques give the best results when supported strongly by all levels of the management and employee teams and if there are persistent efforts on process improvisation with a negligible margin for errors.

Now that we know the several benefits of TQM, needless to say, it should be an integral management technique for every organization.

Because Quality matters!

Recommended Articles

This has been a guide to Total Quality Management Benefits. Here we discussed the definition, cycle of TQM, and the benefits of Total Quality Management. You can also go through our other suggested articles to learn more –