Total Quality Management Notes

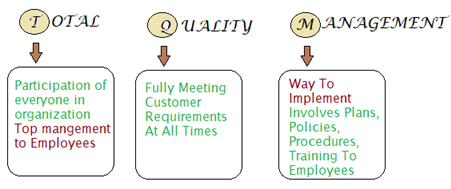

Total quality management notes describe a long-term success management approach by satisfying the customer. When we procure any service/product or even buy fruits from the roadside vendor, quality is an important parameter to consider. And so to provide quality, total quality management comes into the picture. ISO (International Organization for Standardization) defines TQM as “a management approach of an organization centered on quality, based on the participation of all its members and aiming at long term success through customer satisfaction and benefits to all members of the organization and society.”

The general perspective is that quality management is considered to be the responsibility of quality personnel and not of an organization as a whole. But as per the above definition TQM involves the participation of the entire organization towards continuous improvement in services, processes and work culture. Below is the pictorial representation that will help in understanding the concept of Total Quality Management Notes.

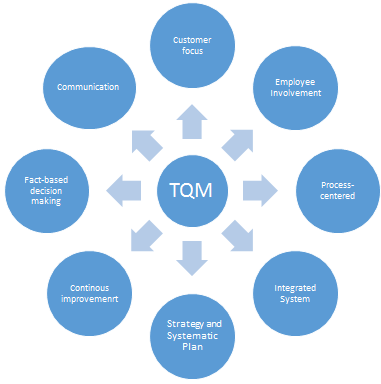

Principles of Total Quality Management Notes

To follow the structured organizational approach, Total Quality Management Notes was coined.

1. Customer Focus

The purpose of quality management is to provide customer satisfaction. With customer focus as an approach, the organization provides services or products meeting the customer expectations. From having several quality checks to friendly support centers, the ever-improving quality can be achieved. Organizations that are more customer focused are the one with larger customer share in the market.

2. Employee Involvement

As Total Quality Management Notes requires the involvement of every employee, it’s the responsibility of the organization to foster the employee-friendly work culture. The work done by employees should be appreciated and their opinions and feedback are taken into consideration. A workplace that encourages employees to give their best achieves continuous improvement in quality.

3. Process-Centered

This process needs to be well defined and need to be monitored for any deviation during the execution. Best practices can be adopted in this approach.

4. Integrated System

Although the processes are divided vertically structured departments, it is horizontally that they interconnect cross-functionally. For example, manufacturing depends on the inventory of the procurement. These horizontal processes need to be modeled properly. Adopting standards IS0 9000 or any quality standard suitable to company requirements helps in integrating the systems.

5. A Strategic and Systematic Plan

A strategic and systematic approach is needed to achieve the organization’s goals and visions. Incorporating quality as part of the strategic plan as the core element is based in TQM.

6. Continuous Improvement

One of the popular approaches in quality management is continuous improvement. It implies to finding creative ways to implement existing processes. This, in turn, helps in being more competitive and meeting the expectations of stakeholders.

7. Fact-Based Decision Making

The performance of an organization can be found from the data collected and analyzed for various parameters. To improve the decision, this data needs to be considered. An accurate decision can be taken if a proper fact-based decision model is created.

8. Communication

This is the building block of a successful business. Communication plan and training employees on communication etiquettes goes a long way in fostering healthy work culture. Communication involves internal amongst the employees and external with the stakeholders. Effective communication makes opinions and feedbacks easier.

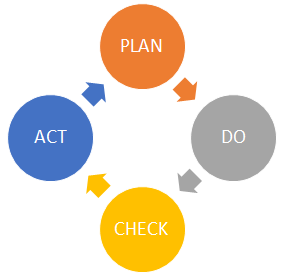

So this is the principles of TQM. To implement this principle, the PDCA cycle was coined by William Deming. It is also known as the Deming cycle/circle. DMAIC (Define, Measure, Analyze, Improve, Control) is the adoption of PDCA in six sigma.

PDCA Cycle

PDCA cycle falls under below four categories:

- Plan

- Do

- Check

- Act

PDCA is considered to cycle because it is based on continuous improvement. Any new idea to improve the existing processes goes through the PDCA cycle.

Plan

A thorough plan with smart goals for improvement is the first phase for Total Quality Management Notes. The plan is checked for the availability of the resources and also if fits the stakeholder’s requirement.

Do

This phase involves the implementation and realization of the plan created for the improvement of processes. Outputs and other parameters are measured and results are documented.

Check

In this, results are monitored and analyzed to match with the plan. The difference known as planning-gap is measured. If the gap is significant, root-cause analysis is carried out for the same.

Act

Once the detected planning –the gap is significant, it’s the time to act quickly. Adjustments are made in the plan and the cycle is initiated again.

Benefits of Total Quality Management Notes

We have seen the concept of total quality management in previous sections and now let’s move ahead to with benefits it provides to the organizations and business as a whole:

- Since TQM is based on the intention to satisfy the customer needs, it focuses on market requirements. It is universal to be used and so helps in understanding the needs of the market.

- It is suitable for changing markets or emerging products. Adaptable to the change.

- Increase in productivity as redundant processes are eliminated.

- Removal of waste and as it helps identify best practices in the processes. This also reduces the cost of repairs, support, warranty, and repair.

- Increase in the skills of employees owing to the continuous improvement and high-quality standards.

- Enhances the trust of stakeholders and customers in the organization because of the quality services provided.

- Improvement in the communication amongst employees and stakeholders too.

- Encourages a healthy work environment as the feedback of employees is taken into consideration.

There are numerous advantages of Total Quality Management Notes and but now let’s see some of the disadvantages.

Disadvantages of Total Quality Management Notes

- The major drawback of this method is that it requires organization-wide efforts. The entire leadership team needs to be on the same grounds when it comes to implementing. Commitment to high levels is expected.

- The employees may be adamant to change the existing processes that they are following for years. Always looking for better ideas can be strenuous for some.

- Methods like six sigma, lean, kaizen are gaining popularity as they don’t require the involvement of the entire company. Departments or teams can implement these in their respective work.

Although disadvantages can be grave, with strenuous efforts these can be reduced. So this was about total quality management. It maybe a gigantic step for implementation but long-term results are beneficial to the companies, business,es or even small-scale enterprises.

Recommended Articles

This has been a guide to Total Quality Management Notes. Here we discussed the PDCA Cycle, advantages, and disadvantages of Total Quality Management Notes. You can also go through our other suggested articles to learn more –