What is Vertical Integration?

Vertical integration is a business strategy in which a company grows its operations across various stages of production or the supply chain, often by purchasing or merging with other companies that operate at controlling different levels of the production process. This is usually done by acquiring or merging with other companies involved in different stages of the production process. Vertical integration can include expanding from raw material extraction to manufacturing, retail distribution, or any combination in between. It gives companies more control over their products, operations, and costs.

Types of Vertical Integration

The types of vertical integration are:

- Forward Integration: This occurs when a company moves downstream in the supply chain. In other words, it takes control of activities closer to the final customer. For example, a manufacturer opening its own retail stores or distribution centers is an example of forward integration.

- Backward Integration: This happens when a company moves upstream in the supply chain. It takes control of its suppliers or sources of raw materials. A car manufacturer, for instance, might purchase a steel factory to secure a consistent supply of metal for its production process.

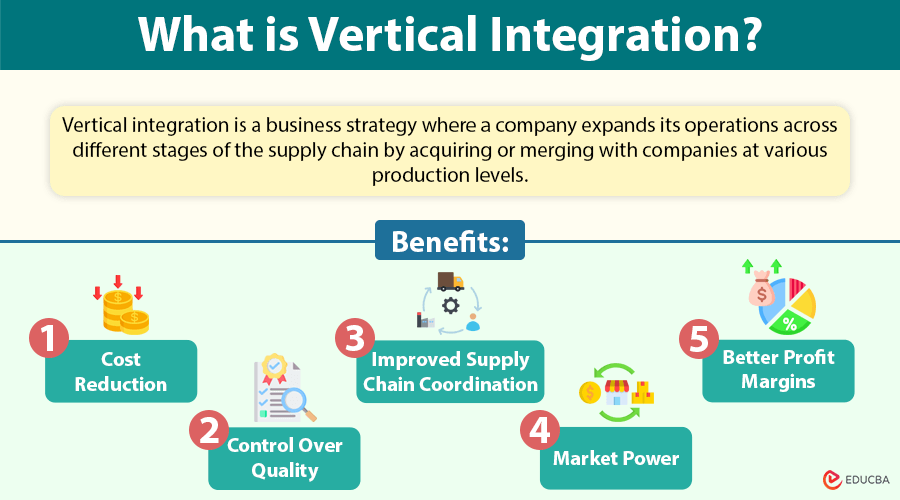

Benefits of Vertical Integration

- Cost Reduction: It can help companies lower costs by eliminating intermediaries like suppliers or distributors. It can also help companies make their operations simpler, resulting in more efficient production and lower costs.

- Control Over Quality: By controlling more steps of the production process, a company can exercise greater oversight of the quality of its product. This is especially important for products where quality control is vital, like pharmaceuticals or food production.

- Improved Supply Chain Coordination: Managing different stages of production allows for better coordination, reducing delays and ensuring a steady supply of materials or products. This can also prevent shortages and disruptions in the supply chain.

- Market Power: A company can increase its market power by controlling key stages in the production or distribution process. For instance, if a company controls both the production of goods and the retail outlets, it can exert more influence over prices and demand.

- Better Profit Margins: With fewer middlemen, the company can keep more of the profit from each product sold, resulting in higher margins and greater profitability.

Drawbacks of Vertical Integration

- High Costs: Although vertical integration can lower costs over time, the initial investment required can be substantial. Companies may need to purchase or build new facilities, invest in new technology, or hire additional employees to manage the new stages of production.

- Lack of Flexibility: A vertically integrated company may find it more difficult to adapt to changes in the market. If the company is heavily invested in one part of the supply chain, it may struggle to pivot or diversify its business model.

- Increased Complexity: Managing multiple stages of production or distribution adds complexity to a company’s operations. This may require new management skills, additional resources, and more time for oversight.

- Risk of Overextension: Companies that expand too much through vertical integration may be stretched too thin. Overextension can lead to inefficiencies, quality control issues, and scaling problems.

Real-World Examples of Vertical Integration

- Apple: One of the best-known examples of vertical integration is Apple. The company designs its products, manufactures many key components (like chips), and operates its retail stores. This allows Apple to maintain tight control over its product design, pricing, and customer experience.

- Tesla: Tesla has also embraced vertical integration by producing many of its car components in-house. It manufactures its own batteries, electric motors, and even some of the software that powers its vehicles. Tesla also runs its own network of charging stations, which is another way it integrates its supply chain.

- Amazon: Amazon exemplifies both forward and backward integration. It has built its own supply chain, from manufacturing products to operating its own logistics and delivery network. It also moved into retail through the acquisition of Whole Foods, giving it control over more aspects of its sales process.

- McDonald’s: McDonald’s is an example of backward integration. It owns or has contracts with many of its suppliers, such as beef and potato producers, ensuring a steady and controlled supply of ingredients for its restaurants.

When is Vertical Integration a Good Strategy?

Vertical integration can be an effective strategy under the following conditions:

- Cost Reduction Opportunities: It can help improve efficiency and reduce overall expenses when there is the potential to lower costs by eliminating intermediaries and streamlining operations.

- Need for Quality Control: In industries where product standards, consistency, and quality are critical, controlling more stages of the production or supply process ensures that the company can uphold high-quality standards and reduce variability.

- Managing Supply Chain Risks: When the supply chain is vulnerable to disruptions, vertical integration offers greater control over raw materials, production, and distribution. This helps companies safeguard against risks such as supply shortages or delays.

- Maximizing Profit Potential: If a company wants to capture a larger share of the profits within the supply chain, owning more of the value chain—from production to retail—can help increase profitability by eliminating middlemen and maximizing control over pricing.

However, vertical integration may not always be the best choice if the costs and risks outweigh the benefits. In cases where a company is better off focusing on its core competencies and working with specialized suppliers or distributors, it may choose to remain less integrated.

Final Thoughts

Vertical integration is a powerful strategy that can help businesses gain control over their operations, reduce costs, improve efficiency, and increase market power. However, it also comes with challenges, such as high investment costs and the potential for overextension. Businesses need to thoughtfully assess the pros and cons of vertical integration, taking into account their future goals, the state of the market, and the resources they have at hand.

Frequently Asked Questions (FAQs)

Q1. Can small businesses benefit from vertical integration?

Answer: Yes, small businesses can adopt partial vertical integration to reduce costs and increase control, such as sourcing raw materials directly or selling directly to consumers via online platforms.

Q2. How does vertical integration impact competition?

Answer: Vertical integration can give companies a competitive edge by controlling critical stages of production or distribution. However, excessive integration could lead to antitrust concerns or reduced competition in the market.

Q3. Can vertical integration lead to environmental benefits?

Answer: Yes, vertically integrated companies can adopt more sustainable practices by streamlining supply chains and reducing transportation or waste. For example, companies owning their production facilities may implement eco-friendly technologies.

Q4. How do mergers and acquisitions fit into vertical integration?

Answer: M&A is a common method of achieving vertical integration. In this method, a company acquires suppliers, distributors, or complementary businesses to gain control of more supply chain stages.

Recommended Articles

We hope this guide helps you understand the potential of Vertical Integration for your business growth. Explore these recommended articles for more insights on effective business strategies and supply chain management.